Performance Characteristics of Large Tank Breathing Valve The function of the breathing valve Under normal conditions, the breathing valve ensures the safety and sealing of the storage tank; and also minimizes the evaporation loss of the medium in the storage tank. The breathing valve starts working under the following abnormal conditions: Working principle The breathing valve is a ventilation device ,widely used in the top of the tank, which is used to maintain the air pressure balance inside and outside the tank, and prevent the tank from sinking and warping. By controlling the exhalation pressure and vacuum degree of the tank, also reduce the evaporation loss of the medium in the tank . Therefore, the breathing valve should have two functions: releasing positive pressure and negative pressure. According to the working principle, there are three kinds: The performance comparison At present, in the domestic large storage tank, the traditional gravity […]

Mechanical Articles

Introduction – Pressure Transmitter Pressure transmitters are critical components in various industrial processes, but their handling requires strict adherence to safety precautions. This comprehensive guide outlines essential precautions to ensure the safe operation of Pressure Transmitter in industrial settings. Proper Installation Procedures – Pressure Transmitter When installing pressure transmitters, it’s crucial to follow manufacturer guidelines and specifications precisely. Ensure compatibility with the application and calibrate the transmitter accurately before installation. Adhere to safety standards such as ISO 5167 for flow measurement. Handling and Transportation During handling and transportation, prioritize the protection of pressure transmitters from physical damage and environmental factors. Utilize appropriate lifting equipment and secure packaging to prevent accidents or equipment damage. Adhere to proper storage procedures to maintain transmitter integrity. Electrical Safety Measures In working with pressure transmitters, it is imperative to follow electrical safety protocols rigorously. Ensure proper grounding of […]

The Brief Introduction of Cooling Tower The cooling tower,uses water as a circulating coolant to absorb heat from a system. And discharge it into the atmosphere to reduce the water temperature. Its use of water and air flow contact after the exchange of cold and heat to produce steam. And, steam volatilization to take away the heat to achieve evaporative heat dissipation. Following, heat transfer and radiation heat transfer principle to disperse industrial. or refrigeration air conditioning generated in the waste heat to reduce the water temperature of the evaporative heat dissipation device. To ensure the normal operation of the system, the device generally barrel-shaped, so called cooling tower. How it works Equipment Cooling tower an equipment that uses the contact of water and air to disperse the waste heat. General in industry or refrigeration and air conditioning through evaporation. Basic principle The basic principle of its work is: After […]

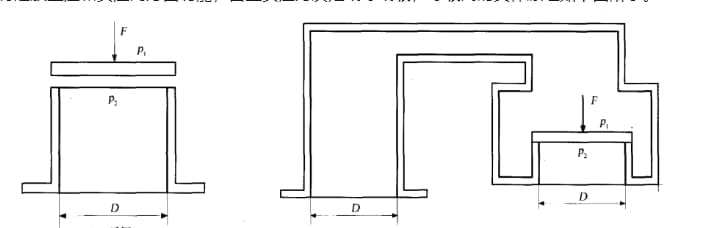

Brief Introduction of Breathing Valve The breathing valve is an equipment that not only ensures that the storage tank space is isolated from the atmosphere within a certain pressure range, but also can communicate with the atmosphere when exceeding or below this pressure range. Its function is to prevent the tank from being damaged by over pressure or vacuum, and at the same time reduce the evaporation loss of the storage liquid. The setting can not only reduce the gas emission in the tank, thereby reducing the pollution to the atmosphere, but also prevent the tank from being damaged by over pressure or destabilized by ultra-vacuum, which plays a certain role in promoting safety and environmental protection. It is mainly composed of a seat, a cover, a protective cover and two groups of opening and closing devices controlled by vacuum and pressure. The opening and closing device comprises a valve […]

Purpose and Principle of Metal Hose Setting 1.The advantages and uses The metal hose has the advantages of compact structure, solid connection, good flexibility, light weight, small size, flexible bending, easy installation, corrosion resistance, good temperature resistance, no aging, high pressure, good tightness, long service life and so on, compared with rubber plastic or other materials. It has 3D compensation function. In the pipe system, it is an extremely effective element for temperature compensation, eliminating mechanical displacement, absorbing vibration and reducing noise. The use of metal hose in the design of petrochemical equipment has greatly improved the intrinsic quality of engineering design. 2.Purpose and principle 2.1 Purpose of setting the metal hose The main purpose of using metal hoses in engineering is to thermal compensate the relationship, eliminate mechanical displacement, absorb vibration, reduce noise, move flexibly, and easily change the direction of fluid movement. 2.2 Setting rules for metal hoses […]

Gear Run Out Measurement Gear run out measurement is an important method used to evaluate the precision of gear manufacturing. The main purpose is to measure the radial run out and end run out of the gear to ensure the roundness and motion accuracy of the gear. Common methods for measuring gear run out are: Gear run out instrument. This method uses a gear run out instrument, a tool specifically designed to measure the integrateness of gear elements, which measures the radial run out of the gear ring, that is, the maximum run out of the probe when it is in double-sided contact with the tooth height in the groove or on the gear within a revolution of the gear. Height gauge method of measurement. The gear is installed in the gauge, the coaxiality is maintained, the height gauge is used to measure the different positions of the tooth tip, […]

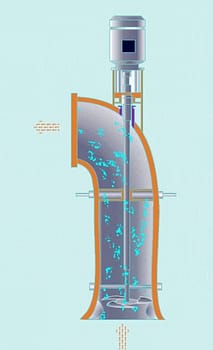

Thickener types and application fields First, horizontal thickener Horizontal thickener is a kind of thickener commonly used. It is a thickener with rotor and tank as the main components. The equipment is simple in structure, small in size and easy to use, and can be widely used in mining, chemical industry, building materials and other fields. The rotor of the horizontal thickener can be designed into different shapes according to different requirements, such as the common barrel shape, conical shape, symmetrical impeller shape and so on. At the same time, the horizontal thickener can also be designed according to different requirements, including single slot, double slot, multi-slot and so on. Second, vertical thickener The vertical thickener is another commonly used thickener. Unlike the horizontal thickener, the main component of the vertical thickener is a rotating cylinder and its internal impeller and deflector. The process of the equipment acting on the […]

The working principle of the stacker reclaimer Stacker and reclaimer is a kind of material handling equipment widely used in ports, docks, steel mills and power plants. It is mainly used to stack bulk materials from one place to another, or to collect and store them centrally from multiple places. The following is the working principle of the stacker reclaimer: The stacking part usually includes a rotating cantilever and a set of material handling devices. When the stacker starts stacking, the cantilever first removes the material from the yard and then delivers it to the designated stacking area via the material handling device. During the conveying process, the material is generally passed through a belt conveyor or chain conveyor and finally transported to the top of the pile area. Take-up section Take-up section usually includes a retractable scraper and a set of support devices. When the reclaimer begins to pick […]

Run Out Test After Machining, Theory and Practice Abstract: This paper provides an in-depth exploration of the run out test carried out after the machining process. It examines the significance, methods, applications, and limitations of this test in ensuring the quality and precision of machined components, with specific examples included. Introduction: The run out test holds extreme importance in the post-machining phase as it assesses the conformance of components to specific tolerance requirements. A thorough understanding of the intricacies of this test is crucial for attaining high-precision machined parts. Main Body: Definition and Purpose: Clarify the meaning and rationale behind the run out test, for example, testing the roundness of a shaft. Test Methods: Describe the various techniques utilized in conducting the test, such as using a dial indicator to measure the run out. Significance in Machining: Highlight its significance in ensuring quality and dimensional accuracy. For instance, in a […]

FPSO Topside Module Manufacture – Key Considerations Abstract: This paper provides an overview of the Floating Production, Storage, and Offloading (FPSO) topside, discussing its critical components and functions, FPSO Topside Module Manufacture. Furthermore, it delves into the manufacturing process of the FPSO topside module, highlighting essential considerations and best practices to ensure efficient and safe production. Introduction: Floating Production, Storage, and Offloading (FPSO) vessels have revolutionized offshore oil and gas production, especially in deepwater fields. The topside of an FPSO, which refers to the upper part of the vessel above the waterline, plays a crucial role in these operations. This paper aims to explain what an FPSO topside is and explore the manufacturing considerations vital for its production. What is FPSO Topside? The FPSO topside comprises the processing facilities, control rooms, living quarters, and helideck, among other essential components. It serves as the operational hub for offshore drilling and production […]

The Classification of Diaphragm Pumps Diaphragm pump, also known as control pump, is the evolution of the reciprocating piston pump in the 1970s on the basis of the increase of diaphragm chamber. It is a new type of conveying machinery, and it is the most novel type of pump in China. It is different from the ordinary pump class, it is the main type of actuator, by accepting the control signal output of the modulation unit, with the help of power operation to change the fluid flow, often with the power of air, electric devices, liquid media and so on. The three types of diaphragm pumps 1.Pneumatic single diaphragm pumpThe pneumatic diaphragm pump uses air as the power source, which is a positive displacement pump by the reciprocating deformation of the diaphragm. Its working principle is similar to that of the plunger pump. Pneumatic diaphragm pump has four materials: engineering […]

Differences Between Centrifugal Pump and Axial Flow Pump? What is the differences between these two kinds of pump?Centrifugal pump and axial flow pump have a wide range of applications in industry, here to introduce the difference and application of the two pumps. In general, centrifugal pumps are suitable for high head and small flow situations, while axial flow pumps are suitable for large flow and low head situations. Learn more our project quality managemet, QAQC and third party inspection (TPI), NDT practices thru below link. https://www.jsc-safe.com/practice-article-blog/

Mineral processing plants require a storage buffer to bridge differences in production rates betweenmining and processing. Where coarse ores are processed, such as coal or hard rock, this buffer maybe an ore stockpile or silo. For wet-mining processes, e.g. dredging or hydraulic mining, or where f ine ores are slurried close tothe mining face, a surge-bin is used to contain the plant feed and smooth out the variations in miningrates. These bins have gradually evolved from simple storage vessels to units that are now frequentlypart of the mineral separation process itself, such as providing a desliming function to removedeleterious ultrafine gangue. This feed conditioning is often essential to achieve the levels of plantperformance required in times of declining ore grades and or where inherent ore characteristicsmake separations harder to achieve. To achieve these dual roles requires careful consideration of bin design factors such as geometryand lining selection and increased use […]

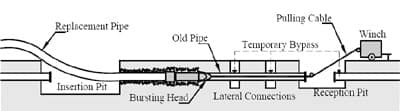

Trenchless Technology Trenchless Construction Drilling Pipe Trenchless technology represents a kind of subsurface construction methodology that necessitates minimal or no continuous trenching. Constituting a swiftly expanding segment of the construction and civil engineering domain, it can be delineated as “a set of techniques, materials, and machinery that can be employed for installing fresh or substitute underground infrastructure, or for revamping the prevailing ones, with negligible interruption to surface traffic, commerce, and other pursuits.” Trenchless Technology Trenchless Construction Drilling Pipe Trenchless construction encompasses various methods such as tunneling, microtunneling (MTM), horizontal directional drilling (HDD), also referred to as directional boring, pipe ramming (PR), pipe jacking (PJ), moling, horizontal auger boring (HAB), and other underground pipeline and cable installation techniques that minimize excavation. Large-scale subsurface projects like those employing a tunnel boring machine (TBM) or drilling and blasting methods are extensions of this concept on a grander scale. The distinction between trenchless […]

How to measure the compression for Mechanical Seal of Double Support Centrifugal Pump? Step 1: Measure the distance between bearing box and suspension contact surface and bearing box and bearing skin end face. a. Use a depth rule from the contact plane between the bearing box and the gland to the contact plane between the bearing box and the end face of the bearing skin (e.g.; Distance is 109.4mm minus vernier caliper thickness 4mm=105.4mm). b. Use vernier calipers to measure the contact plane between bearing and gland to the contact plane between bearing box and suspension (e.g.; Distance is 115mm minus depth gauge thickness 5mm=110mm).The number of a is 105.4mm and the number of b is 110mm= the distance between bearing box and suspension contact surface and bearing box and bearing skin end surface is 4.6mm. Step 2: Install the shaft sleeve and moving ring on the shaft. The purpose […]

Vacuum Ceramic Filter Characteristics Parameters The most important operating parameters of disc filters are the height of the slurry tank, agitation and the intensity and rotation speed of the disc as these will determine the cake formation and drying times. It is important to continuously agitate the slurry in order to prevent sedimentation of the solids. Excessively high agitation intensity may affect cake formation or change the particle size distribution of the product. One of the most commonly used agitators for filtration using vacuum disc filters is an oscillating cradle-type agitator located in the bottom of the basin, which requires fairly high rotation speeds to form homogeneous slurry. For processing rapidly settling high concentration slurries, bottom-feed rotary disc filters are usually used. Stage 1: Filtration During the filtration stage, the low vacuum applied to the filter removes the filtrate from the internal passageways of the discs. The slight pressure difference […]

Vacuum Filter Ceramic Filter A vacuum ceramic filter is designed to facilitate the separation of liquids from solids, primarily for the dewatering of ore concentrates. This device comprises various components such as a rotator, slurry tank, ceramic filter plate, distributor, discharge scraper, cleaning device, frame, agitating device, pipe system, vacuum system, automatic acid dosing system, automatic lubricating system, valve, and discharge chute. While its operation and construction principles bear similarities to a conventional disc filter, the key difference lies in the use of a finely porous ceramic disc as the filter medium. This ceramic disc material exhibits inert properties, boasts a long operational lifespan, and demonstrates resistance to a wide range of chemicals. To optimize performance, it is crucial to consider the various factors that impact the overall efficiency of the separation process. Some of the key variables influencing the performance of a vacuum ceramic filter include solid concentration, the […]

How to measure the compression of mechanical seals? Sealing compression measurement steps:Before measuring the compression of the seal, it is necessary to understand the phase position relationship of each part of the seal to avoid calculation errors in the measurement process. Measure the dimensions of the bushing positioning table to the sealing surface Measurement of gland positioning surface to static ring sealing surface Pay attention to the selection of measuring points when measuring, generally more than 3 points should be measured symmetrically; Measure gland sealing surface to positioning table dimensions When measuring the gland to the sealing surface, it is generally necessary to measure more than 3 points symmetrically; When the measurement data difference is too large, check whether the gland is deformed or corroded;Checking whether the static ring installation is in place is the basic element to ensure the accuracy of measurement data; Measure the dimensions from the bushing […]

Why Close or Open Gate Ralve Half Turn? First, the basic structure of the gate valve. The gate valve is a kind of lift by the gate to cut off the slurry, with simple structure, wear resistance, good sealing, easy operation and so on. Its basic structure includes valve body, gate plate, packing, movable bearing and manual device. Second, why should the gate valve return half a circle. 1.the closing and opening of the gate valve need to be completed by the movement of the gate, and the opening or closing of the gate needs to be rotated at a certain Angle. The half turn is to ensure the tightness and stability of the valve. 2.at the same time, the steel material has a certain elasticity, and the half circle is to prevent exceeding its elastic deformation range, resulting in screw damage. Third, the role of half a circle. 1.Ensure […]

Classification and Working Principle of Steam Trap With the continuous improvement of people’s awareness of environmental protection, energy conservation and emission reduction have become a hot topic of social concern. The trap is a kind of energy-saving equipment came into being under this background, it can reduce the system pressure, reduce the energy loss, for the enterprise to bring considerable energy-saving benefits. This paper will introduce and analyze the principle, type and selection of trap. First, the principle of steam trap Steam trap is an automatic control valve, the main role is in the steam pipeline and equipment, timely elimination of condensate to ensure the stable operation of the system. The working principle of the trap is based on the physical law – the principle of thermodynamics. When the steam passes through the pipe, its temperature is higher than the surrounding environment, so it will emit heat, and the temperature […]

The Oil Circuit Cleaning Frequency of Compressor Ensure the safe operation of turbine compressor units, the oil circuit must be clean and free of impurities. Because even a small amount of impurities into high-speed running bearings, seals, regulating valves and turbine bearings and governors that share a single oil system may cause serious failures. Burn out the bearings, make the regulating valves and governors fail, and endanger the safe operation of the entire unit. Therefore, the newly installed oil circuit system must be carefully cleaned.First to remove the oil, iron filings, welding slag, oxides, dust and other impurities in the pipeline and its accessories. Ensure that the oil circuit is smooth. The regulating mechanism is accurate and sensitive. The unit is safe to operate. After each deep inspection of the machine, the oil system should also be cleaned. The oil circuit cleaning method The oil circuit cleaning method is generally […]

Troubleshooting and Solutions for Pump Failure to Discharge Water The reason why the pump failure to discharge water is analyzed as follows: 1.There is air in the water inlet pipe and pump 1) The pump is not filled with enough water before starting, sometimes it seems that the water has been flooded from the vent hole, but the pump shaft is not rotatedThe gas is completely discharged, resulting in a little air remaining in the intake pipe or pump body. 2) The horizontal section of the water inlet pipe in contact with the water pump should have a downward slope of more than 0.5% in the direction of the reverse flow, and connect the water pump inletOne end is the highest, not completely level. If it is tilted upward, the intake pipe will retain air, reducing the water pipe and pumpThe vacuum degree affects water absorption. 3) The packing of […]

Steel plate base material (raw material) inspection is a crucial step in ensuring the quality and performance of steel products. This process involves a range of inspection methods, each with its own reference standards and key considerations. In this article, we will explore the advantages of steel plate base material (raw material) inspection, focusing specifically on the Q355B grade, and discussing various inspection techniques and their associated standards. Visual Inspection Firstly, let’s consider the visual inspection method. This involves a thorough examination of the steel plate’s surface for any visible defects or irregularities. Visual inspection is a quick and cost-effective way to identify potential issues, such as cracks, scratches, or discoloration. While it may not provide quantitative data, it serves as a valuable initial screening tool. Mechanical Testing Mechanical testing is another important aspect of steel plate base material (raw material) inspection. Tensile testing, for instance, measures the […]

Q235B and S235J0: Key Differences, Welding Considerations, Chinese Steel Mills’ Production and Advantages Q235B and S235J0 are two widely used structural steel grades, each with its unique characteristics and applications. Understanding the differences between these two grades, along with the production capabilities and advantages of Chinese steel mills, is crucial for making informed decisions in engineering projects. This article aims to delve into these distinctions, referencing their respective standards, highlighting welding considerations, and discussing the production and advantages of Chinese steel mills. Q235B and S235J0: Reference and Properties Q235B, according to the Chinese standard GB/T 700, is a carbon structural steel known for its strength and ductility. It is widely used in various structural applications in China and other Asian countries. On the other hand, S235J0, defined by the European Norm EN 10025, is a structural steel grade commonly found in European projects. Both grades have similar yield strengths but […]

Stainless Steel – Fabrication: An Insight into the Material and Key Considerations During Fabrication Stainless steel, known for its corrosion resistance and durability, is a crucial material in the fabrication industry. Its unique properties make it suitable for a wide range of applications, from industrial equipment to architectural structures. In this article, we will delve into the nature of stainless steel, explore its fabrication process, and highlight the key considerations during the process. What is Stainless Steel? Stainless steel is an alloy of iron with a minimum of 10.5% chromium. The chromium content forms a thin, invisible, corrosion-resistant layer on the steel’s surface, protecting it from oxidizing and rusting. In addition to chromium, stainless steel may also contain other elements such as nickel, molybdenum, titanium, and nitrogen, which further enhance its properties. Stainless steel is classified into several types based on its composition and properties. The most common types include […]

Centrifugal Pump is Evacuated Phenomenon How to Do? Centrifugal pump in the practical application, there will always be a variety of conditions, one of the many reasons for centrifugal pump failure when the phenomenon of evacuation, always make you feel very headache. What if the centrifugal pump is evacuated? After the pump is pumped, or during the process of pumping1) The vibration of the pump body is large, and the dynamic and static rings of the mechanical seal will continue to intermittently collide, resulting in leakage, and the failure of the mechanical seal structure in serious cases;2) The compression of the dynamic and static ring of the mechanical seal is the sum of the medium pressure and the pretension force of the spring, when evacuated, the medium pressure will not be there, the contact pressure of the dynamic and static ring will become smaller, and the seal will fail;3) After […]

Briefly Analyz The State of Pump Outlet Valve Under normal circumstances, starting the centrifugal pump, according to the specification should first fill the pump chamber with media, close the outlet valve, and then open the pump, the purpose is: on the one hand to prevent the starting current is too large damage to the motor; On the other hand, prevent the instantaneous loss of pressure after starting the pump, resulting in pump cavitation. But many problems cannot be generalized! For low flow and low head pumps, closing or not closing the outlet valve is not a problem. For large pumps, the outlet is often slightly opened, in order to prevent the pressure difference between the front and back of the valve after starting, and the outlet valve is not easy to start, so slightly open the outlet valve opening. Some centrifugal pumps will open the outlet valve slightly due to […]

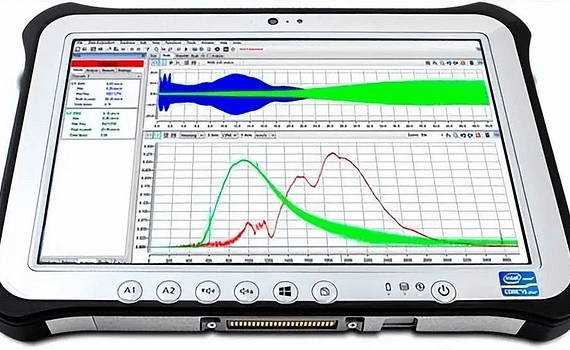

Six Steps of Vibration Analysis for Field Faults In the field fault analysis, first of all, we should have a macro understanding of the equipment, and get the surface cause according to the external characteristics. Then the mechanism analysis of its main vibration characteristics is carried out to judge the deep-seated reasons. 1. Understand the vibration history When the vibration of the machine increases suddenly or gradually, determine whether the vibration is stable during the period, if it is not stable, which parameters are associated with it, and so on. For example, the sudden increase of vibration may be the sudden unbalance of the rotor and the sudden weakening of the stiffness. Whether the amplitude instability is associated with load adjustment, temperature change, start and stop, etc. 2. Understand the maintenance situation If the vibration before and after the start of the maintenance, if the vibration before the maintenance is […]