Quality

20 Years+ Quality Management, QAQC Quality Assurance, Quality Control, Third Party Inspection. – ISO 9001 and Recognition from Wide customer companies.

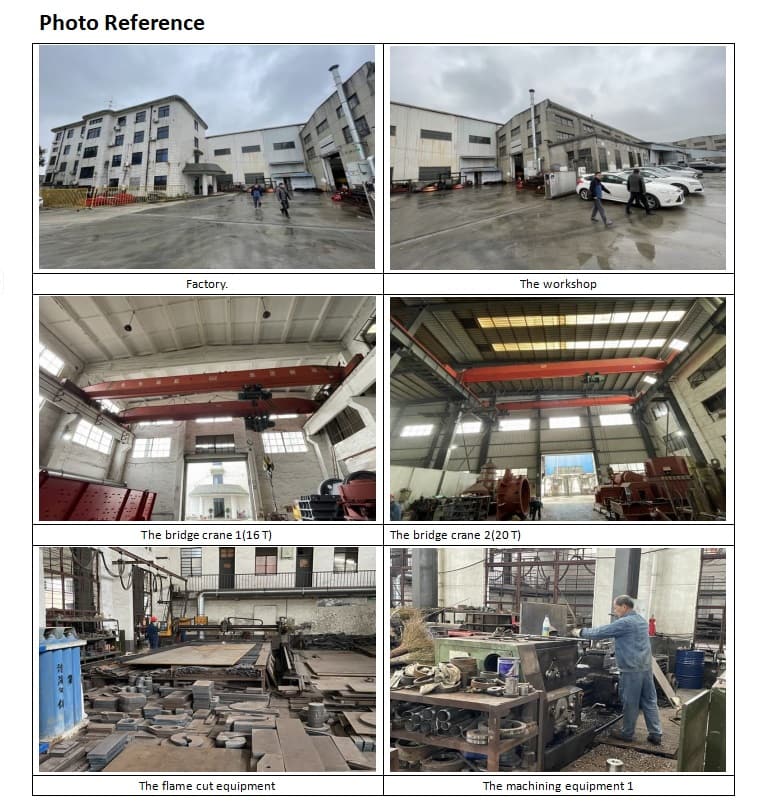

Supplier Audit, Supplier Assessment

A supplier audit is an independent and objective assessment of a supplier’s processes or products against benchmarked criteria, whether that’s international regulations or in-house standards.

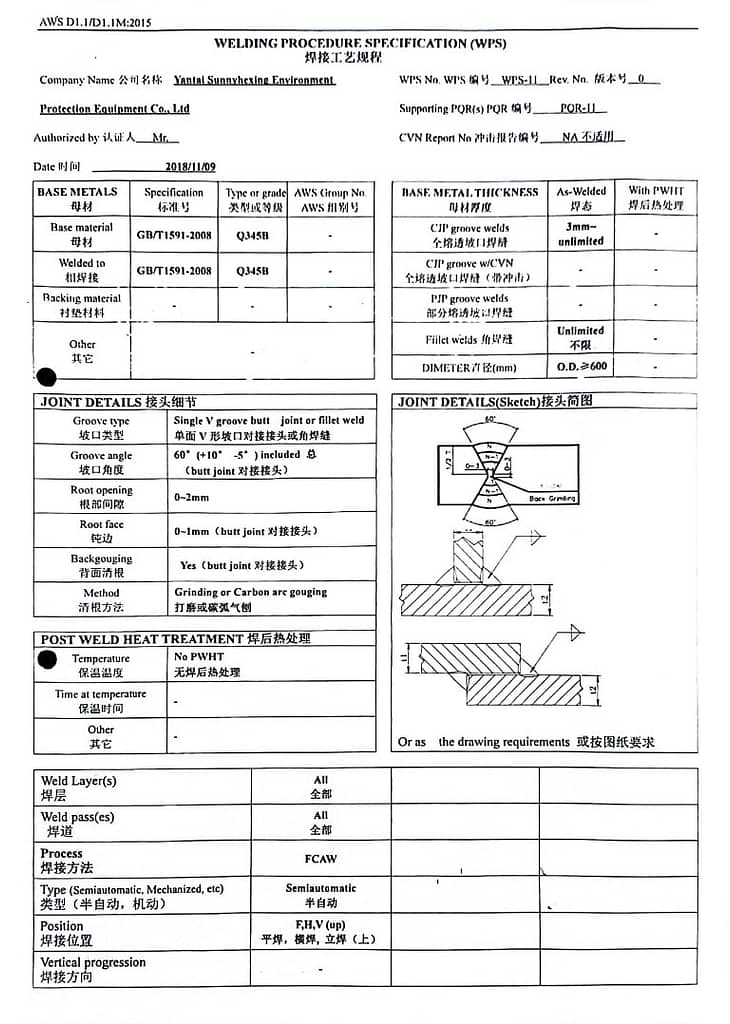

WPS - Welding Procedure Specification

Written and detailed document for welding operations

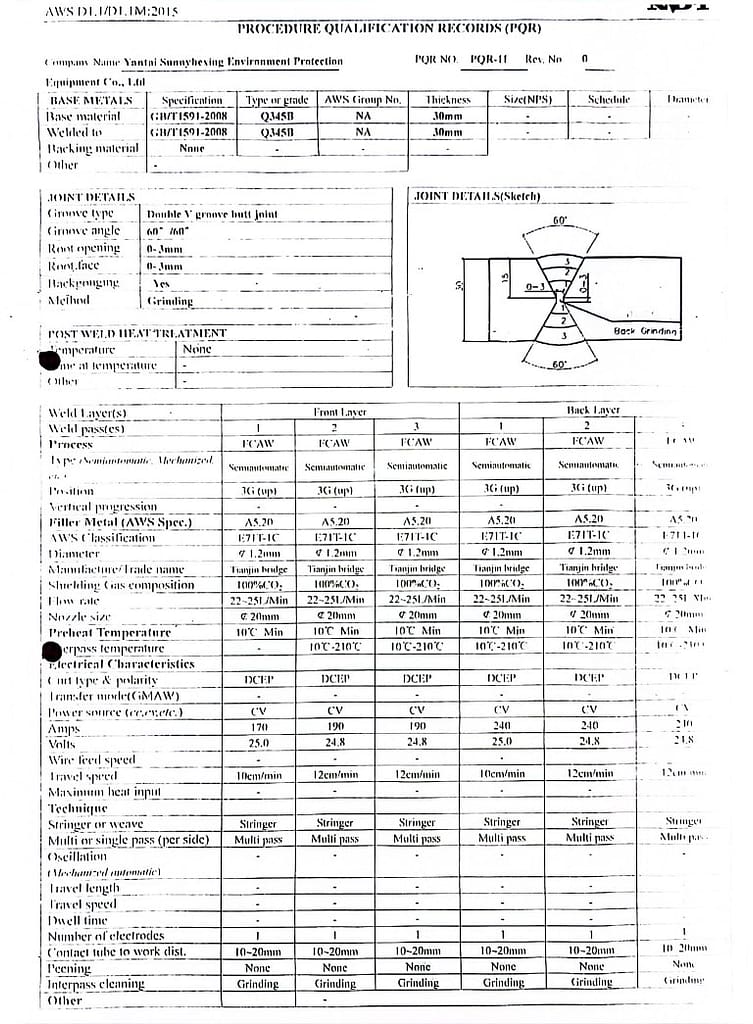

PQR - Procedure Qualification Record

Document that consists of procedures for creating and testing the sample welds, and the final results

Welding Inspection, Welding Supervisor

CWI, SCWI, CSWIP 3.1, CSWIP 3.2, IWE

International Standards such as ASME, AWS D1.1, AS 1554.1, API are the basic standards equipped by our inspectors of many projects, as JSC SAFE takes part in numerous international standard projects.

Coating Advisor, Coating Inspection

Painting Inspector and Painting Advisor with NACE 2 (II), NACE 3 (III)

NDT - CNAS, ISO 17025, ISO 9001, DNV

RT – Radiography Testing; UT – Ultrasonic Inspection; MT – Magnetic Particle; PAUT – Phased Array Ultrasonic Testing; PT – Penetrant Testing; VT – Visual Testing; LEVEL III (LEVEL 3) Expert Service & Training; TOFT; PMI

Thickness Measurement

Ultrasonic thickness gauges can be set up for metals, plastics, composites, fiberglass, ceramics, and glass.

Raw Material Inspection

Raw Material Inspection, Certificates Inspection, Material Verification & Testing, PMI – Positive Material Identification

Hydrostatic Test

JSC SAFE has completed thousands of meters of piping and pressure vessels’ hydro tests. With capabilities ranging from small skids to large pipeline systems, from leakage tests to super high pressure.

Mechanical Inspection, Installation, Commissioning

Equipment for Mining. –

Crusher, Mill, Thickener, Screen, Kiln, Hopper, Flotation Tank, Reagent Tank, Bag House, Filter, Conveyor, Belt, Stacker, Reclaimer, Air Reservoir, Rub Lined Pipe, Carbon Steel Pipes, Slurry Pump, Fire Pump, Electric Motor, Hydrocyclone, Gear Box, Crane, Compressor, Magnetic Separator, Vacuum Separator, Longwall and associates, Fire Fighting Truck, Crane Truck. Etc.

Equipment for Marine and Offshore. –

Windlass & Mooring Winch, Steering gear, Life boat and Rescue boat, Galley and laundry equipment, Accommodation ladder, Metal windows & doors, Anchor, Anchor chain, Weather tight hatches, Firefighting equipment and lifesaving equipment, Main engine, Diesel Engine Generator, emergency generator set, Plate cooler, Air compressor, Pump (Centrifugal & Gear), Purifier, Sewage treatment plant, CO2 fighting system, Fans, Bilge water separator, Boiler, Valves remote control system, Level measuring system, Incinerator, Fresh water generator, Mineralizer, Sterilizer, Oxygen & Acetylene bottle, Stern tube seal, Intermediate shaft bearings, Propeller, Crane, Air reservoir, Hydrophore tank, Engine room water-spray system, Main engine lube oil auto-filter, Butterfly valves, Ballast Water Treatment Plant, Eductors, GRE Piping. etc.

E&I - Electrical and Instrumentation

Electrical equipment inspected. –

Switchgear, Switchboard, Switch cabinet, MCC (Motor Control Center), PDB (Power Distribution Box), GIS (Gas Insulated Switchgear), RMU Prefabricated substation (Mini-substation), Circuit breaker, Disconnector, Current transformer, Voltage transformer, Capacitor, Capacitor bank, Copper tube busbar, Pole. Etc.

Voltage of the equipment (LV/MV/HV). –

400V, 12.7kV, 22kV, 33kV(40.5kV), 66kV(72.5kV), 220kV(245kV)

Routine Test

A routine test is a test to which each equipment is subjected after or during manufacture. The test helps identify failures and/or unacceptable tolerances in manufacturing that functionality tests may not detect and may create an electrical hazardous situation

The purpose of routine tests is to evaluate several safety parameters which the manufacturing process could affect. E.g. wiring-related issues, warning labels, core transformers, and insulation.

FAT - Factory Acceptance Test

A process within the manufacturing and quality assurance phase of industrial equipment or systems. It involves a series of tests and inspections conducted by the manufacturer or supplier to ensure that the product meets the specified requirements, design criteria, and functionality before it is delivered to the customer.

Pre-Shipping Inspection

Packing Inspection, Loading Inspection, Pre-Shipping Inspection – Packing List, Packing Process, Fix & Lashing, Marking, Certificate of Fumigation, Customs Clearance, Customs Seal. etc

Expediting

The expediting of raw materials, machines, equipment, parts, systems and subsystems in fabrication, manufacturing, logistics is a common but necessary path for many companies. Reasons for expediting include missed contracted delivery dates, damage to stock, supplier-related issues and tight customer requirements.

Expediting can be a burdensome and stressful strategy in the purchasing process. Many stakeholders relying on delivery dates are involved in this process, especially when parts are critical. Even though “chasing” suppliers is not a job a buyer is supposed to do, it ends up doing so most of the time.

Lack of accurate and timely information, use of multiple forms of communication and absence of a formal process for expediting are some of the challenges that buyers must deal with on a daily basis while discussing revised delivery dates.

Document Control, MDR

Manufacturer’s Data Report, Consists necessary technical and manufacturing data and records, for a clear traceability after the project was delivered.

Let us know your enquires, we'll handle the rest.

Can’t wait to give you a surprise at our amazing services and show how our services align with your requirements.