TGOOD Switchboards Introduction TGOOD switchboards are making waves in the electrical industry. High-Quality Materials Constructed with top-grade components for durability. Innovative Engineering Feature advanced designs for enhanced performance. Safety First Approach Offer multiple layers of protection and prevention. Versatile Usage Scenarios Suitable for diverse industrial and commercial needs. Energy Efficiency Focus Contribute to lower power consumption and savings. Customization Availability Tailored to meet specific project requirements precisely. Smooth Installation Process Easy to set up and commission with minimal hassle. Low Maintenance Demands Designed for convenient servicing and upkeep. Smart Technology Integration Compatible with modern monitoring and control systems. Successful Project Implementations Showcase real-world examples of efficient usage. Continuous Research and Development Stay updated with the latest technological advancements. Compliance with Industry Regulations Adhere to strict standards for quality and safety. Environmental Considerations Minimize the ecological […]

NDT

CHINT Switchboards Introduction CHINT switchboards have gained significant recognition in the market. Quality Assurance Built with high-quality materials and strict manufacturing processes. Innovative Design Offer modern and efficient layouts for easy operation. Safety Features Provide comprehensive protection against electrical hazards. Versatile Applications Suitable for a wide range of industries and settings. Energy Efficiency Help save power and reduce operational costs. Customization Options Tailored to meet specific customer needs and project requirements. Easy Installation Streamlined process for quick and hassle-free setup. Maintenance Convenience Designed for simple and efficient servicing. Smart Monitoring Compatibility Integrate with advanced monitoring systems for better control. Case Studies of Success Demonstrate successful installations and their positive impacts. Research and Development Efforts Constantly evolving to meet changing industry demands. Compliance with Standards Adhere to strict international and domestic regulations. Environmental Friendliness Minimize the […]

GE Switchboards Introduction GE switchboards are highly regarded in the electrical industry. Reliability and Durability Built to withstand demanding conditions and last for years. Advanced Technology Integration Feature cutting-edge components for efficient operation. Safety Protocols Ensure protection against electrical risks. Versatile Applications Suitable for various sectors and environments. Energy Efficiency Enhancements Contribute to reduced power consumption. Customization Options Tailored to meet specific project requirements. Installation and Setup Ease Quick and straightforward commissioning process. Maintenance-Friendly Design Simplify servicing and minimize downtime. Smart Monitoring Capabilities Enable real-time data tracking and analysis. Case Studies of Success Show effective implementations and benefits. Innovation and Development Focus Stay ahead with continuous research and improvements. Compliance with Industry Standards Meet strict regulations for quality and safety. Environmental Considerations […]

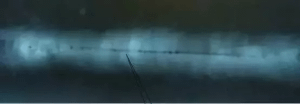

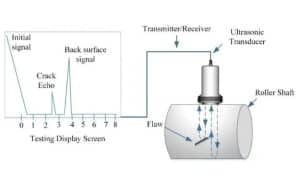

Application of NDT Technology in Iron and Steel Industry Molten Steel through smelting, casting, rolling, heat treatment and other processes, can be obtained with different specifications of the finished product. But in the production process, steel bars are easy to appear a variety of internal and external defects, such as shrinkage, white spots, internal cracks, scarring, cracks, depression and folding. At present, the technologies used to detect the internal defects of steel bars are X-ray testing and ultrasonic testing respectively, and some of them, such as penetration testing, ultrasonic testing, magnetic flux leakage testing and eddy current testing, etc. , is the most common in the detection of surface defects. 1 Ultrasonic testing technique The ultrasonic testing technique is effective by the physical phenomenon that the sound beam entering the material is reflected at the heterogeneous interface. Because ultrasound technology can play a role not only in the detection of surface […]

A Brief Analysis of the Procedure of Ultrasonic Nondestructive Testing 1. Principle of ultrasonic testing Ultrasonic flaw detection is a non-destructive testing method, which uses the difference of acoustic properties of materials and their defects to examine the internal defects of materials. 2. Characteristics of ultrasound The ultrasonic beam can be concentrated in a specific direction and propagate along a straight line in the medium, and has good directivity. Ultrasonic wave attenuates and scatters when it propagates in medium. Ultrasonic wave will produce reflection, refraction and wave form conversion on the interface of dissimilar medium, and the reflected wave from the defect interface can be obtained by using these characteristics. Ultrasound is much more powerful than sound. The transmission loss of ultrasonic wave in solid is very small and the detection depth is very large. inspection of parts with large thickness. 2.1 Disadvantages: It is difficult to display the defects […]

Common Methods of Weld Inspection 1. Eddy Current Eddy current testing (ET) is one of the non-destructive testing methods in industry Fast and effective detection of surface and subsurface cracks High detection rate without paint removal Wide coverage, fast scanning speed, save time Replace penetrant and magnetic particle testing 2. Industrial microscopes Check the cross section of the weld using our imaging solution All the measurements are completed in one step to realize fast detection Suitable for t-joints, lap joints and corner joints and all weld sizes Calibrate the image to obtain reliable results 3. Regular ultrasound High quality defect detection, very easy to use Its rugged, ergonomic design allows it to be used in challenging environments The intuitive interface is useful for both experienced and novice inspectors A full range of UT probes for detecting and measuring welding defects 4. Remote visual inspection Check hard-to-reach areas Best image quality […]

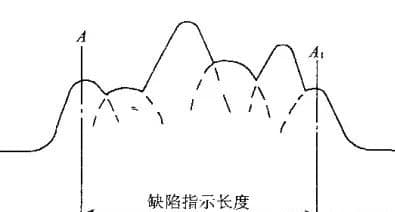

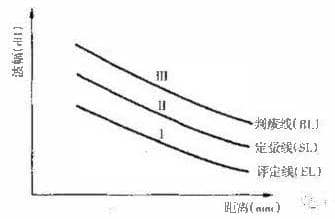

Method for Determination of Defect Length in Ultrasonic Testing Method for Determination of Defect Length in Ultrasonic Testing – When the defect size in the workpiece is larger than the beam section, the length measurement method is usually used to determine the defect length. The length measurement method is based on the defect wave height and the probe moving distance to determine the size of the defect. The defect length determined by the prescribed method is called the indicated defect length. Because the orientation, property and surface state of defects in the actual workpiece can affect the echo height of defects, the indicating length of defects is always less than or equal to the actual length of defects. The length measurement method can be divided into relative sensitivity method, absolute sensitivity method and end-point peak value method. 1. Relative sensitivity length measurement The relative sensitivity length measurement is based on […]

Factors Affecting the Quantification of Defects in Ultrasonic Testing Factors Affecting the Quantification of Defects in Ultrasonic Testing – In ultrasonic testing, it is necessary to find the location of the defect quickly and accurately, and judge its shape, size and type, the error plays a decisive role in the reliability and accuracy of the whole ultrasonic testing results. 1. Instrument effects 1) Horizontal linearity Horizontal linearity, also called baseline linearity or scan linearity, refers to the extent to which the reflected wave distance displayed on the scanning line of the flaw detector is proportional to the distance of the reflector. The level linearity of the instrument directly affects the ranging precision and the defect location. 2) Vertical linearity Vertical linearity, also known as amplification linearity or amplitude linearity, refers to the height of the reflected wave on the flaw detector screen is proportional to the received signal voltage. The […]

How to Distinguish Forging Crack, Heat Treatment Crack and Raw Material Crack? How to Distinguish Forging Crack, Heat Treatment Crack and Raw Material Crack? – Type of crack: Raw Material Crack, heat treatment crack, forging crack, etc.. Forging cracks can be subdivided into: (1) Forging crack caused by raw material defect; (2) Forging cracks caused by improper forging process. Purpose of forging: (1) Forming requirements; (2) Improve the internal structure of the material, refine the grain, uniform element composition and structure; (3) Make the material more compact, streamline distribution is more reasonable; (4) Through a reasonable post-forging heat treatment, for the next process services. Therefore, forging forging raw material internal defects is the responsibility. Large-scale castings and forgings often start from ingot forging directly. There must be a lot of casting defects in ingot, obviously, reasonable forging, can be one of the so-called”Defects” forging. Therefore, the rationality of forging process […]

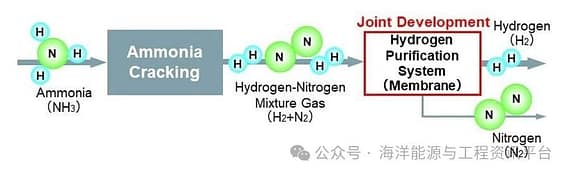

Japan Energy and Shipping – Development, Advancements In the realm of energy and shipping, Japan is making significant strides. Two Japanese companies are at the forefront of these developments, focusing on hydrogen purification systems from ammonia cracking gases and making strategic moves in the ammonia supply chain and clean ship fuel sectors. Tokyo Gas’ Asset Sale Tokyo Gas, a leading Japanese utility provider, has sold minority stakes in four LNG projects along the Australian coast. Through this asset sale, MidOcean Energy, managed by EIG, has acquired interests in the Gorgon, Queensland Curtis, and Pluto LNG projects, while Inpex, a Japanese company, has obtained the rights in the Ichthys LNG project. This move not only reflects the changing dynamics of the energy market but also demonstrates the strategic decisions being made to optimize resources and partnerships. The Ammonia Supply Chain Initiative HI Corporation, Hokkaido Electric Power Company, Hokkaido Mitsui Chemicals, Inc., […]

NDT Practice Ultrasonic Testing UT – Forging and Casting 1. NDT Casting Because of the coarse grain size, poor sound permeability and low signal-to-noise ratio of the castings, it is difficult to detect the defects, to detect defects by reflecting off an internal surface or defect. NDT Forging Casting The magnitude of the reflected sound energy is a function of the directivity and nature of the inner surface or defect and the acoustic impedance of such a reflector, it is therefore possible to detect the location of defects, wall thickness, or the depth of defects beneath the surface by using a variety of defects or acoustic energy reflected from the inner surface. As a widely used non-destructive testing method, the main advantages of ultrasonic testing are: high sensitivity, which can detect small cracks. Its main limitations are: it is difficult to interpret the reflected waveforms of disconnection defects with complex […]

The Principle and Characteristics of Ultrasonic Testing (UT) 1 Ultrasonic Testing can be used in quality control, raw material inspection, process improvement and other aspects, but also an indispensable means of equipment maintenance. 2 The main applications of ultrasonic testing are the detection of macro-defects in the workpiece and the measurement of material thickness. According to different characteristics, ultrasonic detection can be divided into many different methods: 2.1 Classification by principle: Ultrasonic pulse reflection, Time of Flight Diffraction (TOFD) and so on. 2.2 Sort by display: A-type display, ultrasonic imaging display (b, C, D, P scan imaging, dual-control array imaging, etc.) . The ultrasonic pulse reflection method with A-type display is one of the five conventional nondestructive testing techniques, the other four are Radiographic Testing: Radiographic Testing, Magnetic Particle Testing, Penetrant Testing, and Eddy Current Testing. 3 The principle of ultrasonic testing is essentially the use of ultrasonic and material […]

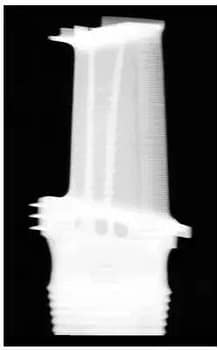

Advantages and Limitations of Radiographic Testing 1. There is a direct record of the test results-negatives Because the information recorded on the film is very rich and can be preserved for a long time, radiography becomes a kind of real, direct and traceable detection method. 2. The projection image of defect can be obtained, and the defect qualitative and quantitative is accurate. Among all kinds of nondestructive testing methods, the relative defect qualitative and quantitative is standard. In quantitative terms, the length and width of volumetric defects (pores, slag inclusions) are also accurately determined, with an error of approximately zero mm. However, for area defects (such as cracks, non-fusion) , such as the size of defect tip (height and width of opening) is very small, the image extension on the film may be indistinguishable, and the quantitative data will be small. 3. The detection rate of volume defects is very […]

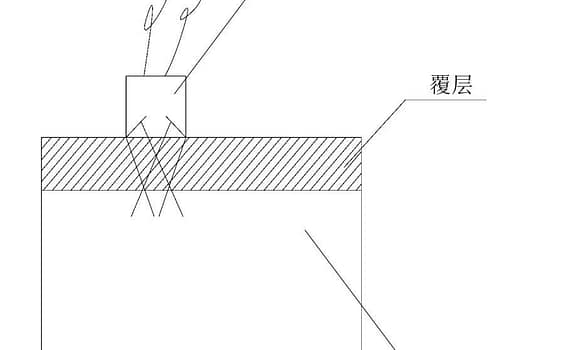

Four Best NDT Methods for Corrosion under Thermal Insulation Four Best NDT Methods for Corrosion under Thermal Insulation – many literatures and data have proved that Cui is a very common and complicated phenomenon, and it is very difficult to find this kind of corrosion, and it needs a lot of time and economic cost. The corrosion under insulation layer is the corrosion phenomenon of pipeline or equipment covered by insulation layer due to the entry of water and corrosive substances. This corrosion is usually hard to detect because it is usually hidden under an insulating layer, traditionally detected by: Remove pipe surface coverings; Check the pipes; Restore the original appearance of the surface coverings. This process involves a lot of cost and logistical issues. Even cutting the cladding alone is a very time-consuming and labour-intensive process, which may be further complicated if the covering material contains asbestos and needs […]

The Necessity of Ultrasonic Testing in Welding of Metallic Materials The Necessity of Using Ultrasonic Testing in Welding of Metallic Materials – There are many problems in the welding process of metal materials, the most important of which are three aspects: internal defects, macro defects, micro defects. In order to better analyze the importance of using ultrasonic nondestructive testing, we first look at these three aspects of defects in detail. Internal defects in welding of metallic materials The internal defects of the welding structure of metal materials are: slag residue left in the weld during workpiece welding, and one is in the process of material welding. A hole formed by encasing a gas in molten metal. Another is in the workpiece welding process between the material and the formation of cracks. Macroscopic defects in welding of metallic materials The macroscopic defects of the welding structure of metallic materials are: the […]

NDT Test Timing of Heat Treatment Status NDT Test Timing of Heat Treatment Status – Many standards require that the timing of NDT testing be performed after heat treatment. Here are 4 common“Fires” for heat treatment. Annealing: The steel work piece is heated to 30-50 ° C above AC3 and held for a period of time to homogenize the austenite structure and refine the grains, followed by slow cooling in the furnace (or buried in sand or lime) to below 500 ° C, a heat treatment process in which air is cooled to room temperature. It can eliminate the defects of coarse structure, ferrite or carbide, composition segregation and internal stress in the workpiece during hot working. Normaliz: A heat treatment process in which a steel workpiece is heated to a suitable temperature above the critical point AC3 or ACCM for a certain period of time to achieve full austenization […]

High Carbon Steel Welding Defects and Preventive Measures As high carbon steel tends to be hardened, it is easy to appear hot and cold cracks during welding. Measures to prevent thermal cracking Control the chemical composition of the weld, strictly control the content of sulfur and phosphorus, increase the content of manganese, in order to improve the weld structure and reduce segregation. Control the cross-section shape of the weld, width-depth ratio is slightly larger to avoid segregation of the weld center. Suitable welding parameters, welding sequence and welding direction should be selected for high rigidity welding parts. When necessary, take pre-heating and slow cooling measures to prevent the formation of hot cracks. Improve the alkalinity of electrode or flux, in order to reduce the impurity content in the weld, improve the segregation degree. Prevention of cold cracking Preheating before welding and cooling after welding can not only reduce the hardness […]

Abstract: This paper focuses on the Arctic LNG 2 project and its related fabrication and module yards in China. It explores the significance and challenges of this project, as well as the role played by Chinese yards in its implementation. Introduction: The Arctic LNG 2 project holds significant importance in the LNG industry. This study aims to examine the fabrication and module yards in China involved in this project. The Arctic LNG 2 Project Overview: A brief introduction to the project’s background and objectives. Discussing its scale and expected impact on the energy market. Fabrication and Module Yards in China: Identifying the key yards participating in the project. Exploring their capabilities and expertise in LNG fabrication. Technical Aspects and Challenges: Analyzing the technical requirements and challenges faced during the project. Highlighting the solutions adopted by the Chinese yards. Quality Control and Safety Measures: Discussing the importance of quality control and […]

Causes of Lamellar Tearing and How to Prevent? Causes of Lamellar Tearing and How to Prevent? Three general categories: The first one is lamellar tearing induced by cold crack at weld toe or root in haz. The second is the heat-affected zone along the inclusion cracks, is the most common engineering layered tearing. The third type of matrix crack far away from the heat-affected zone (haz) usually occurs in the thick plate structure with more MNS. There are many factors that affect lamellar tear, including: 1. The type, amount and distribution of non-metallic inclusions are the essential reasons of lamellar tearing, which is the root of anisotropy and mechanical properties difference of steel. 2. In the course of welding, the thick-wall welded structures with Z-constraint stress bear different Z-constraint stress, post-welding residual stress and load, which are the mechanical conditions that cause lamellar tearing. 3. It is generally believed that […]

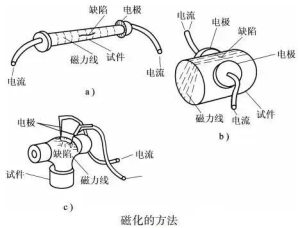

NDT – Magnetic Testing (MT) / Magnetic Particle Inspection (MPI) for Pressure Vessel NDT – Magnetic Testing (MT) / Magnetic Particle Inspection (MPI) is widely used in nondestructive testing of pressure vessels. The testing methods are as follows: The principle is: The magnetic field will be applied to the specimen, steel and other strong magnetic materials can be strongly magnetized by the magnetic field. If there is a crack on the specimen, and the direction of the crack and the direction of magnetization is right angle, then the magnetic pole appears at the crack, and magnetic leakage field is produced. When fine particles of magnetic particles enter the leakage field, they are attracted and left behind. Because the leakage magnetic field is wider than the crack, the accumulated magnetic powder can be easily seen by the naked eye. When the magnetization is high enough, even if the crack is very […]

What are the Welding Appearance Inspection Items? Weld is the bonding part of a welded piece. Weld can be generally divided into: flat weld, fillet weld, one-sided weld, one-sided weld double-sided shaped weld. The welds can also be divided into butt welds and fillet welds according to their own cross-sectional forms. Butt Welds: no penetration of the butt welds stress is very small, there is a serious stress concentration, penetration of the butt welds referred to as the butt welds. Fillet Weld: the connection plate edge need not finish processing, plate seamless, weld metal directly filled in the two pieces of welding form right angle or bevel in the region. The Weld appearance inspection can guide welders and welding inspectors to ensure the whole work and project welding quality. Welding appearance inspection items 1. Various welding defects Undercut: Groove or dent in base metal of weld toe due to improper […]

Analysis of the Types and Basic Characteristics of Welding Cracks With the development of steel, petrochemical industry, ship and electric power industry, the welding structure tends to be large-scale, large-capacity and high-parameter, some also work in low temperature, cryogenic, corrosive media and other environments. Therefore, all kinds of low-alloy high-strength steel, medium and high-alloy steel, super-strength steel, as well as a variety of alloy materials are increasingly widely used. However, with the application of these steels and alloys, there are many new problems in welding production, and the most common and serious one is welding crack. Cracks sometimes occur during welding, sometimes during placement or operation, and so-called delayed cracks. Because this kind of crack can not be detected in the manufacture, the harm of this kind of crack is more serious. There are many kinds of cracks in welding process. According to the present research, according to the nature […]

What is it Incomplete Penetration? Incomplete Penetration during welding refers to the defect caused by no melting between the base metal and the weld metal does not enter the root of the joint. According to the welding method of welding parts, it can be mostly divided into root and middle Incomplete Penetration. The root is not welded because the liquid weld metal does not enter the blunt edge of the root, most of them exist in the single side welding of the V-shaped or U-shaped groove, the middle is because the liquid metal does not enter the middle blunt edge, most of them exist in the double V or double U-sided welding. The existence of Incomplete Penetration in the weld will reduce the effective area, and seriously cause the mechanical properties of the decrease such as the strength of the welding parts. Incomplete Penetration will also cause stress concentration and […]

The Importance of Visual Testing (VT) in Steel Structure Welding Quality Inspection The Importance of Visual Testing (VT) in Steel Structure Welding Quality Inspection – With the unique advantages that traditional civil structures do not have, steel structures have developed rapidly, involving more and more different types of buildings, such as bridges, high-rise buildings, stadium, etc. . Welding is an important technology of steel structure component connection. The quality of welding will directly affect the strength and safety of steel structure. The welding quality of steel structures can be tested by different non-destructive testing methods, such as ultrasonic testing and radiographic testing to detect internal defects in welds, magnetic particle inspection, penetration inspection and visual testing are used to detect weld surface and near-surface defects. The importance of visual testing in welding quality inspection of steel structures is described. In the weld inspection, visual testing is often ignored by the […]

Common Crack Types of Pressure Vessels and Pipelines and their NDT Techniques Common crack types of pressure vessels and pipelines: Stress corrosion cracking Stress corrosion crack is a common type of crack, which is related to the interaction of internal and external stress and corrosion medium. Common in the boiler steam pipe and container seat, mainly tied in the pipeline outside. When the pressure on the outer surface of the pipeline exceeds the stress limit of the region, it will inevitably lead to the external deformation and cracking of the pressure pipeline. Mechanical Fatigue Crack Mechanical fatigue cracks are common in rotating machinery parts such as impeller, blade and shaft in boiler auxiliary system. This kind of crack mainly includes two stages, namely, the early stage of long crack propagation and the late stage of tangential crack formation. Therefore, the formation of mechanical fatigue crack is related to the running […]

Five Steps to Calibrate Magnetic Testing (MT) Equipment Five Steps to Calibrate Magnetic Testing (MT) Equipment – There are many kinds of magnetic particle testing equipment, from small portable magnetic detector to wet horizontal magnetic detector to high current fixed magnetized power supply for large structures. If you follow ASTM E1444, ASTM E3024, ISO 9934, or NADCAP AC7114/2, you must calibrate your equipment every six months. No matter what type of magnetic particle testing equipment is used, five-step method can be used for equipment calibration. Step 1: verify the standard instrument to be used 1.This work requires standard reference instruments: shunts, ammeters, and excitation timers. Different instruments have different control configurations. Refer to the specification of the standard reference instrument for detailed operating procedures. 2.Check the calibration dates of these standard reference instruments-have they been calibrated in the past 6 months? 3.How much data do you need to test and […]

JSC is an ISO 17025 NDT Lab / Company (CNAS) ISO/IEC 17025:2017 is an international standard specifying requirements for quality and competence in testing and calibration laboratories. The standard requires that such labs prioritise excellent quality practices and develop a reliable quality management system to establish and demonstrate their competence. The full standard is called ISO/IEC 17025, since the certification was created by the International Organization for Standardization in conjunction with the International Electrotechnical Commission. However, many shorten this to ISO 17025 or simply 17025 certification when referring to the standard. Ultimately, ISO 17025 is for any organization that performs testing, sampling or calibration and wants to be sure of the reliability of their results. The simplest way we can put it: if you work in a testing environment that produces measurable results, then ISO 17025 is probably applicable. This may even mean you don’t necessarily call your facility a […]

What are the Ultrasonic Testing (UT) Methods? Ultrasonic Testing (UT) Methods – Sound is a physical phenomenon, although its instantaneous existence is very obvious, but it does not cause any permanent changes. This is why sound (low energy) is ideal for nondestructive testing, where the state of the object under test is determined by obtaining accurate information. For this purpose, a method is needed that produces a definite reaction within the subject without changing its state. “Passivity” is the most important feature that sound is required for material testing. 1. Passive acoustics is also used in the special field of acoustic emission, in which sound waves are generated internally by spontaneous changes in material conditions. Sound waves are mechanical waves and therefore need to act as a medium for conducting them. Whether it is a solid, a liquid, or a gas, each material can be evaluated for its particular effects […]

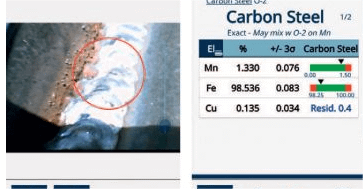

Steel plate base material (raw material) inspection is a crucial step in ensuring the quality and performance of steel products. This process involves a range of inspection methods, each with its own reference standards and key considerations. In this article, we will explore the advantages of steel plate base material (raw material) inspection, focusing specifically on the Q355B grade, and discussing various inspection techniques and their associated standards. Visual Inspection Firstly, let’s consider the visual inspection method. This involves a thorough examination of the steel plate’s surface for any visible defects or irregularities. Visual inspection is a quick and cost-effective way to identify potential issues, such as cracks, scratches, or discoloration. While it may not provide quantitative data, it serves as a valuable initial screening tool. Mechanical Testing Mechanical testing is another important aspect of steel plate base material (raw material) inspection. Tensile testing, for instance, measures the […]

Q235B and S235J0: Key Differences, Welding Considerations, Chinese Steel Mills’ Production and Advantages Q235B and S235J0 are two widely used structural steel grades, each with its unique characteristics and applications. Understanding the differences between these two grades, along with the production capabilities and advantages of Chinese steel mills, is crucial for making informed decisions in engineering projects. This article aims to delve into these distinctions, referencing their respective standards, highlighting welding considerations, and discussing the production and advantages of Chinese steel mills. Q235B and S235J0: Reference and Properties Q235B, according to the Chinese standard GB/T 700, is a carbon structural steel known for its strength and ductility. It is widely used in various structural applications in China and other Asian countries. On the other hand, S235J0, defined by the European Norm EN 10025, is a structural steel grade commonly found in European projects. Both grades have similar yield strengths but […]

Stainless Steel – Fabrication: An Insight into the Material and Key Considerations During Fabrication Stainless steel, known for its corrosion resistance and durability, is a crucial material in the fabrication industry. Its unique properties make it suitable for a wide range of applications, from industrial equipment to architectural structures. In this article, we will delve into the nature of stainless steel, explore its fabrication process, and highlight the key considerations during the process. What is Stainless Steel? Stainless steel is an alloy of iron with a minimum of 10.5% chromium. The chromium content forms a thin, invisible, corrosion-resistant layer on the steel’s surface, protecting it from oxidizing and rusting. In addition to chromium, stainless steel may also contain other elements such as nickel, molybdenum, titanium, and nitrogen, which further enhance its properties. Stainless steel is classified into several types based on its composition and properties. The most common types include […]

Pressure Vessels, Tanks, Skids – Fabrication: An Insight into the Process and Key Considerations Pressure vessels and tanks are essential components in various industries, such as petrochemical, refining, chemical processing, and power generation. These vessels and tanks are designed to store fluids or gases under pressure and must, therefore, be fabricated with utmost precision and care. In this article, we will delve into the fabrication process of pressure vessels and tanks, highlighting the key points that need to be considered during the process. What are Pressure Vessels & Tanks? Pressure vessels and tanks are closed containers designed to hold fluids or gases at a pressure higher than the ambient atmospheric pressure. They are made from various materials, including steel, stainless steel, and alloys, depending on the specific application and the type of fluid or gas they are designed to hold. These vessels and tanks come in a range of […]

How to Explain the Cause of the Welding Defects on the Negative Plate 1. Common welding defects can be classified into four categories: 1) Weld size does not meet the requirements: such as ultra-high, ultra-wide, too narrow, too large difference between height and height, weld transition to the base metal is not smooth. 2) Welding surface defects: such as undercut, Weld, concave, overflowing, no penetration, surface porosity, surface cracks, etc. . 3) Weld internal defects: such as porosity, slag inclusion, cracks, non-fusion, tungsten inclusion, double-sided welding, such as the lack of penetration。 4) The properties of welded joint do not meet the requirements: the mechanical properties and corrosion resistance of welded joint are reduced because of over-heating and over-burning. 2. The damage of welding defects to welded components mainly includes the following a spects: 1) Cause stress concentration The distribution of stress in welded joint is very complex. Where there […]

Welding defects refer to various discontinuities, imperfections, or poor connections in the welded joint that occur during the welding process. These defects can include incomplete fusion, porosity, slag inclusion, undercut, overlap, burn-through, segregation, incomplete filling, and welding cracks, among others. Among these defects, welding cracks and porosity pose the greatest hazards to the performance and safety of welded structures. Welding cracks are gaps that form in the welded joint due to the breakdown of the atomic bonds between metals, caused by welding stresses and other brittleness-inducing factors. Depending on their nature, welding cracks can be classified into various types such as hot cracks, cold cracks, reheat cracks, lamellar tearing, and stress corrosion cracks. For example, hot cracks occur at high temperatures during the welding process. Their shape and temperature zone vary depending […]

Post-weld Heat Treatment is not Entirely Advantageous Post-weld heat treatment – Welding residual stress is caused by non-uniform temperature distribution, thermal expansion and contraction of weld metal, so it is inevitable to produce residual stress with welding construction. The most common method to eliminate residual stress is high-temperature tempering, in which the weldments are heated to a certain temperature and held for a certain time in a heat treatment furnace, taking advantage of the reduction of the yield limit of the material at high temperature, when the internal stress is high, the plastic flow will occur, the elastic deformation will decrease, and the plastic deformation will increase and the stress will decrease. 1) Selection of heat treatment methods The influence of post-weld heat treatment on tensile strength and creep limit of metal is related to the temperature and holding time of heat treatment. The effect of post-weld heat treatment on […]

Why porosity / porosities often appear in welds? Reason 1: The gas is impure Porosity – Preventive measures: gas cylinders regularly clean, in the use of gas cylinders inverted 1-2 hours before opening the valve after the water after use. Reason 2: Surface Oil and rust Preventive measures: cleaning the surface of the workpiece before welding oil, rust, oxide, etc. . Can be used wire brush, shot blasting and other methods to remove. Reason 3: Blocked air passage or air leak Preventive measures: often check the gas system is blocked or gas leakage. Timely cleaning, maintenance or replacement, develop good operating habits. Reason 4: Seal weld without vent hole Prevention measures: butt welding will increase chamfer, the middle does not leave air gap. Leave out part of the weld without welding or until the workpiece cools before welding. Reason 5: Welding Torch angle is too small, air from the rear […]

NDT – UT of Common Types of Defects Echo and False Defects Common Types of Defects Echo and False Defects: Porosity: The echo height of a single pore is low, the waveform is stable, and the reflected wave is approximately the same from all directions, and disappears with a slight movement of the probe. The dense pores are a group of reflected waves whose wave height varies with the size of the porosity. Dot inclusion: The echo signal of dot inclusion is similar to that of dot pore. The echo signal of slagging slag is zigzag, the reflectivity is low, the amplitude is not high, the waveform is often tree-like, there is a small peak on the side of the main peak, the amplitude changes when the probe moves, and it can be detected from all directions, the reflected waves vary in height. Non-penetration: In the thick double-sided weld, the […]

All Kinds of Welding Defects Diagram and How to Prevent Welding Defects Diagram and How to Prevent – Causes of incomplete penetration The main causes of non-penetration are: small groove angle, too narrow root gap or too thick blunt edge, improper selection of welding current is too small, line energy is small, welding speed is too fast. 1、Cold Crack The characteristics of cold cracks are mostly in the heat affected zone near the fusion line between weld bead and base metal, and most of them are transgranular cracks. Cold crack without oxidation color. Cold cracks occur at or with high carbon and alloy content. Cold cracks have a delayed nature, mainly delayed cracks. The quenching tendency of cold crack (and heat affected zone and fusion zone) is serious, resulting in quenching microstructure and embrittlement of joint. High hydrogen content, and gathered in place to form a large number of hydrogen […]

GB/T 41655-2022 “Non destructive Testing – Ultrasonic Testing – Welding, Rolling, and Explosive Composite Coating Testing Techniques” Process Method Interpretation The use of welding, rolling, and explosion processes can achieve metallurgical bonding of one or more metals with different chemical and mechanical properties at the interface to form composite materials. It can greatly improve the thermal expansion, strength, fracture toughness, impact toughness, wear resistance, electrical properties, magnetic properties, and many other properties of a single metal material. It can also be made into composite plates, composite strips, composite foils, composite pipes, composite rods, composite wires, composite profiles, etc. Therefore, such processes are widely used in petroleum, chemical industry, shipbuilding, metallurgy, mining, machinery manufacturing, power, water conservancy, transportation, environmental protection, pressure vessel manufacturing, food, brewing, pharmaceutical and other fields. The interface bonding state of metal composite materials has a significant impact on composite materials, and many composite material product standards classify […]

Australian Wharf Structure Pile Manufacturing Fabrication – Rio Tinto – Amrun Chith Export Facility (2017 – 2018) Standard: AWS D1.1, API RP 2X Australian Wharf Steel Structure, Pile Piling Manufacturing Fabrication – Rio Tinto – Amrun Chith Export Facility Rio Tinto’s Amrun Project located south of the Embley River, between Weipa and Aurukun in Far North Queensland, revolutionised the design and construction of wharf infrastructure through a collaborative approach between Rio Tinto. JSC joined project for Quality Control and NDT during the project. JSC awarded recognition from Rio Tinto for JSC’s performance and efforts for project success. Ref https://www.riotinto.com/en/news/releases/2018/amrun-supports-local-businesses

Mining – Kamoa Mine – Process Plant Fabrication & Equipment FAT (2019 – 2023) Standard: AWS D1.1 Copper Mine Process Plant Fabrication & Equipment FAT – Kamoa Kamoa-Kakula ranks amongst the top 10 largest copper deposits globally, and holds the distinction of being the world’s largest high-grade copper deposit. According to a recent Mineral Resource estimate, Kakula, the second significant discovery at Kamoa, boasts Indicated Mineral Resources totaling 66 million tonnes with a copper grade of 6.59%, along with Inferred Resources of 27 million tonnes at 5.26% copper, using a 3% cut-off grade. Additionally, Kakula also exhibits Indicated Mineral Resources of 192 million tonnes with a copper grade of 3.45%, coupled with Inferred Resources of 101 million tonnes at 2.74% copper, utilizing a 1% cut-off grade. The inclusion of Kakula significantly enhances the combined […]

Material Handling – FMG, Eliwana Mine – Stacker Reclaimer Conveyor Material Handling Conveying System & Accessories FAT (2019 – 2020) Standard: AS 1554.1, AS 5131, AS 2207, AS 1171 Eliwana, situated 96 kilometers west-northwest of Tom Price in Fortescue’s Western Hub within the Pilbara region, stands as one of FMG’s most recent mines and processing facilities. The Eliwana Operations encompass a remarkable 143 kilometers of new railway, a state-of-the-art Ore Processing Facility capable of handling 30 million tons per annum, a Stockpile equipped with a rail-mounted Stacker-Reclaimer combination, and a Train Load Out Facility, all working together to export high-grade iron ore to Fortescue’s Hedland port facility. The Stacker Reclaimer Conveyor Material Handling Conveying System, successfully delivered in September 2020. During Manufacturing, Fabrication, JSC took part in Project Management, Project Control, Fabrication Management, Pre-Assembly, E&I, Document […]

ShipBuilding, Shipping Owner Owning Operation – Barge (2008 – 2020) Class: CCS GangHua Barge 1199 – one of the top 5 biggest barges in China, has made crucial contributions to various shipping and engineering milestone projects. JSC founder Mr REN Hua, senior marine surveyor, the partner of the barge, led his team fully involved in the barge’s commercial, engineering design, construction, commissioning, and operations. GangHua Barge 1199 – one of the biggest barges, involved milestone projects in China. Such as Hong Kong-Zhuhai-Macao Bridge Shipping, Logistics, Construction. ZMPC Mega Cranes Shipping, Logistics & Delivery.

Australian HMAS Coonawarra – Marine Wharf Permanent Steelwork (2020 – 2021) Standard: AS 1554.1, AS 4100, AS 2207, AS 1171 New wharf and approach jetties to join the Australian Defence Force The Permanent Steelworks, fabricated in China. JSC took part in steel structure and piles fabrication supervision, CWI inspection, CSWIP, NACE 2 3 Coat Inspection, Coating Inspection, Painting Advisor, quality inspection, NDT, document control. The Project aim to deliver a brand-new 250-meter-long wharf along with two access jetties. This state-of-the-art facility will significantly enhance the berthing capacity and support services for Royal Australian Navy vessels (HMAS), when completed. Having constructed a plethora of marine facilities across northern Queensland and Western Australia for Australia’s foremost mining companies, and currently involved in upgrading ADF facilities in the Pacific, it’s indeed a privilege to bring our vast experience and expertise to the Northern Territory ….

BHP Marine Wharf – BMA Shiploader and Berth Replacement (SABR), Hay Point – Steel Piles, Structures Fabrication & FAT (2021 – 2022) Standard: AWS D1.1, API SPEC 2W Hay Point – BHP Wharf Steel Structures Piles Fabrication SABR was a brownfields project located within the lease boundaries of BMA’s existing Hay Point Coal Terminal near Mackay, Queensland. It included the disassembly and replacement of one of the existing shiploaders and berths to improve materials handling throughput and cyclonic wave immunity. Jacket pipes and steel structures for SABR project, fabricated in China as several batch of orders. JSC took part in progress coordination, fabrication supervision, Accessories FAT, NDT, and Delivery / Loading. Ref: https://www.bhp.com/news/articles/2023/11/hay-point-celebrates-completion-of-sabr-project

Marine Wharf – FGEN Batangas LNG Terminal – Marine Wharf Modules Steelwork Fabrication & FAT (2021 – 2022) Standard: AWS D1.1, API SPEC 2W FGEN LNG Corporation, a subsidiary fully owned by First Gen Corporation (First Gen), contracted McConnell Dowell to construct and deliver the Interim Offshore Terminal Project (“IOT Project”) situated at the Batangas LNG Terminal, which is a part of the First Gen Clean Energy Complex in Batangas, Philippines. The Permanent Steelworks of the LNG Wharf Terminal was fabricated in China. JSC took part in On Site Engineering Coordination, Fabrication Supervision, Fabrication and Assembly Inspections, Document Control, Accessories FAT, Administration, NDT, Packing and Loading as third-party inspector. The Multi-Purpose Jetty, situated adjacently to the existing jetty, is designed to accommodate various vessels including liquid fuel carriers, LNG carriers, FSRU, and FSUs. The construction […]

Oil & Gas – Arctic LNG 2 Module Fabrication (2021 – 2022) Standard: AWS D1.1, D1.6 JSC awarded NDT contract from one of the Arctic LNG 2 major fabrication yards in China. NDT work includes, RT (X-ray), MT, UT, PAUT, Document Control.

Mining – FMG, Iron Bridge Mine – Process Plant Fabrication & Equipment FAT (2020 – 2022) The Iron Bridge project is a iron ore mine in Australia. The Iron Bridge magnetite mine is anticipated to yield a yearly production of 22 wet million tonnes (wmtpa) of high-quality magnetite concentrate. The initial shipment of ore from this mine is scheduled for the first six months of 2022. With an estimated lifespan exceeding 20 years, the mine boasts a strip ratio of 0.6 and a remarkable 30% mass recovery. Distinct from Fortescue’s haematite operations, Iron Bridge specializes in producing a wet concentrate product. This product is then transported to Port Hedland via a specialized 135-kilometre slurry pipeline, where the process of dewatering and materials handling takes place. Standard: AS 1554.1, AS 4100, AS 2207, AS 1171, AS3000, AS1657, AS5131, AS4041 The Processing Plant, fabricated in China. JSC took […]

Marine Wharf – BCI Mardie Salt & Potash Marine Structures – Steelwork and Steel Piles (2022 – 2023) Standard: AS 1554.1, AS 4100, AS 2207, AS 1171 Delivering new marine facilities to grow Australian exports. 2.4 km long jetty with berthing and mooring dolphins. Steelwork is fabricated in China. JSC SAFE took part in Material Test, Survey, Engineering Design, document control, fabrication supervision, assembly supervision, quality inspection, NDT, administration. The Mardie Salt and Potash Project, commonly referred to as Mardie or the Project, is solely owned by Mardie Minerals Pty Ltd, a subsidiary entirely held by BCI Minerals Limited (BCI). This Project offers a unique and sustainable prospect for establishing a large-scale, multi-generational solar evaporation operation along the Pilbara coast of Western Australia (WA). The Pilbara coast stands out as one of the world’s foremost regions for solar salt production. In this region, five existing solar evaporation salt projects […]