All Kinds of Welding Defects Diagram and How to Prevent

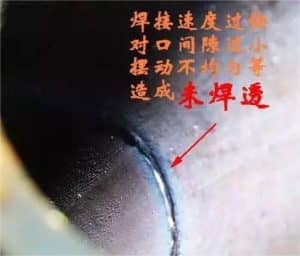

Welding Defects Diagram and How to Prevent – Causes of incomplete penetration

The main causes of non-penetration are: small groove angle, too narrow root gap or too thick blunt edge, improper selection of welding current is too small, line energy is small, welding speed is too fast.

1、Cold Crack

The characteristics of cold cracks are mostly in the heat affected zone near the fusion line between weld bead and base metal, and most of them are transgranular cracks. Cold crack without oxidation color. Cold cracks occur at or with high carbon and alloy content. Cold cracks have a delayed nature, mainly delayed cracks. The quenching tendency of cold crack (and heat affected zone and fusion zone) is serious, resulting in quenching microstructure and embrittlement of joint.

High hydrogen content, and gathered in place to form a large number of hydrogen molecules, resulting in very large local pressure, so that the joint embrittlement;. There is a large tensile stress. Because the diffusion of hydrogen takes time, cold cracks do not appear until some time after welding. Because it is induced by hydrogen, also known as hydrogen induced cracking. To prevent cold cracking, choose alkaline or reduce the content of hydrogen in metal and improve metal plasticity.

To Dry, remove oil, water and rust from weld and adjacent base metal to reduce hydrogen sources. The workpiece is preheated before welding and cooled slowly after welding (the temperature of most materials can be looked up table) , which can reduce the cooling rate after welding, avoid the formation of hardened structure, and reduce welding. Take measures to reduce welding stress, such as symmetrical welding, multi-layer multi-pass welding of small line energy, etc. . Immediately after welding, dehydrogen (post-heat) treatment, heating to 250 °C, holding 2-6 H, so that the hydrogen in the weld metal escape from the metal surface.

2、A thermal crack (also known as a crystalline crack)

The characteristic of hot cracks hot cracks can occur in the weld zone or heat affected zone, along the length of the weld distribution. The microcosmic character of hot crack is cracking along grain boundary, so it is also called intergranular crack. Because of the formation of thermal cracks at high temperature, oxidation color.

Visible immediately after welding. Causes of thermal cracking. There are low melting point eutectic (containing impurities such as sulfur, phosphorus, copper, etc.) in the grain boundary of weld metal. Tensile stress exists in the joint. Appropriate preventive measures, strict control of harmful impurities carbon, sulfur, phosphorus content. Fe and Fes are easy to form eutectic with low melting point, and their melting point is 988 ° C.

Strictly control the cross-section shape of weld to avoid sudden height and flat transition. The range of crystallization temperature is reduced, the microstructure of weld is improved, the weld grain is refined, and the plasticity is improved. The reasonable parameters are determined to slow down the cooling rate of the weld to reduce the welding stress. Such as the use of small line energy, pre-heating before welding, reasonable weld layout.

Learn more our project quality managemet, QAQC and third party inspection (TPI), NDT practices thru below link.-