Analysis of the Types and Basic Characteristics of Welding Cracks

With the development of steel, petrochemical industry, ship and electric power industry, the welding structure tends to be large-scale, large-capacity and high-parameter, some also work in low temperature, cryogenic, corrosive media and other environments.

Therefore, all kinds of low-alloy high-strength steel, medium and high-alloy steel, super-strength steel, as well as a variety of alloy materials are increasingly widely used. However, with the application of these steels and alloys, there are many new problems in welding production, and the most common and serious one is welding crack.

Cracks sometimes occur during welding, sometimes during placement or operation, and so-called delayed cracks. Because this kind of crack can not be detected in the manufacture, the harm of this kind of crack is more serious. There are many kinds of cracks in welding process. According to the present research, according to the nature of the cracks, they can be divided into the following five categories:

1. Hot Crack

Thermal crack is produced at high temperature during welding, so it is called thermal crack. According to the different materials of the weld metal, the hot cracks are different in shape, temperature zone and main reasons, so they can be divided into three types: crystalline crack, liquefaction crack and polygonal crack.

1) Crystal Crack

At the later stage of crystallization, the liquid film formed by low volume eutectic weakens the bond between grains and cracks under tensile stress.

It is mainly produced in the welds of carbon steel and low alloy steel (high content of sulfur, phosphorus, iron, carbon and silicon) and single phase austenitic steel, nickel base alloy and some aluminum alloy. In some cases, crystalline cracks can also occur in the heat-affected zone.

2) High temperature liquefied crack

Under the action of peak temperature of welding thermal cycle, remelting occurs between Haz and multilayer welding, and cracks are produced under the action of stress.

It occurs mainly in high strength steel, austenitic steel and some nickel-based alloy near seam zone or multi-layer welding interlayer. When sulfur, phosphorus and silicon carbon in base metal and welding wire are high, the tendency of liquefaction crack will increase significantly.

3) Polygonal crack

Under the action of high temperature and stress, the defects in the solidified crystal front move and gather, forming a secondary boundary. The polygonal cracks usually occur in the weld or near-seam zone of pure metal or single-phase austenitic alloy, which belongs to the type of hot cracks.

2. Reheat crack

Steel of heavy plate welded construction containing certain precipitation-reinforced alloy elements, in the course of stress-relieving heat treatment or in service at a certain temperature, the cracks in the coarse grain of haz are called reheat cracks. Reheat cracks occur in the coarse-grained parts of haz in low alloy high strength steels, pearlite heat resistant steels, Austenitic stainless steel steels and some nickel-based alloys.

3. Cold Crack

Cold crack is a kind of common crack produced in welding, which is produced after welding at lower temperature. The cold cracks are mainly produced in the heat affected zone (haz) of low-alloy steel, medium-alloy steel, medium-carbon steel and high-carbon steel. In some cases, such as welding ultra-high strength steel or certain titanium alloys, cold cracks also appear on the weld metal.

According to the different types of welded steel and structure, there are different types of cold cracks, which can be broadly divided into the following three categories:

1) Delayed crack

It is a common form of cold crack, and its main feature is that it does not appear immediately after welding, but has a general incubation period, a crack with a delayed characteristic produced by the combined action of quenched structure, hydrogen, and restraint stress.

2) Quenching crack

This type of crack is virtually non-delayed and is found immediately after welding, sometimes in the weld and sometimes in the heat-affected zone. It is mainly a crack which is produced under the action of welding stress and has a quenched structure.

3) Low plastic brittle crack

Some low-plasticity materials, cold to low temperature, due to shrinkage caused by strain exceeds the material itself has plastic reserves or brittle material produced by the crack. Because it is produced at a lower temperature, it is another form of cold crack, but without delay.

4. Lamellar tear

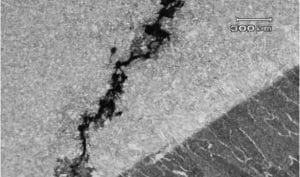

During the manufacturing process of large oil production platform and thick-wall pressure vessel, step cracks parallel to the rolling direction sometimes appear, so-called lamellar tearing.

It is mainly due to the existence of layered inclusions (along the rolling direction) in the steel plate, the stress produced during welding is perpendicular to the rolling direction, resulting in a slightly distant place in the heat-affected zone, “Step” lamellar tearing occurs.

5. Stress corrosion cracking

Delayed cracking in certain welded structures, such as vessels and pipelines, under the combined action of corrosive media and stresses. The factors affecting the stress corrosion cracking are the material of the structure, the type of corrosion medium, the shape of the structure, the manufacturing and welding process, the welding materials, and the degree of stress relief. Stress Corrosion is produced during service.

Learn more our project quality managemet, QAQC and third party inspection (TPI), NDT practices thru below link.-