China Factory Audit Checklist: Ensuring Quality and Compliance

In the global manufacturing landscape, conducting factory audits in China is of paramount importance. This post delves into a detailed China factory audit checklist, providing insights into the various aspects that need to be evaluated to ensure the highest standards of quality, compliance, and operational excellence.

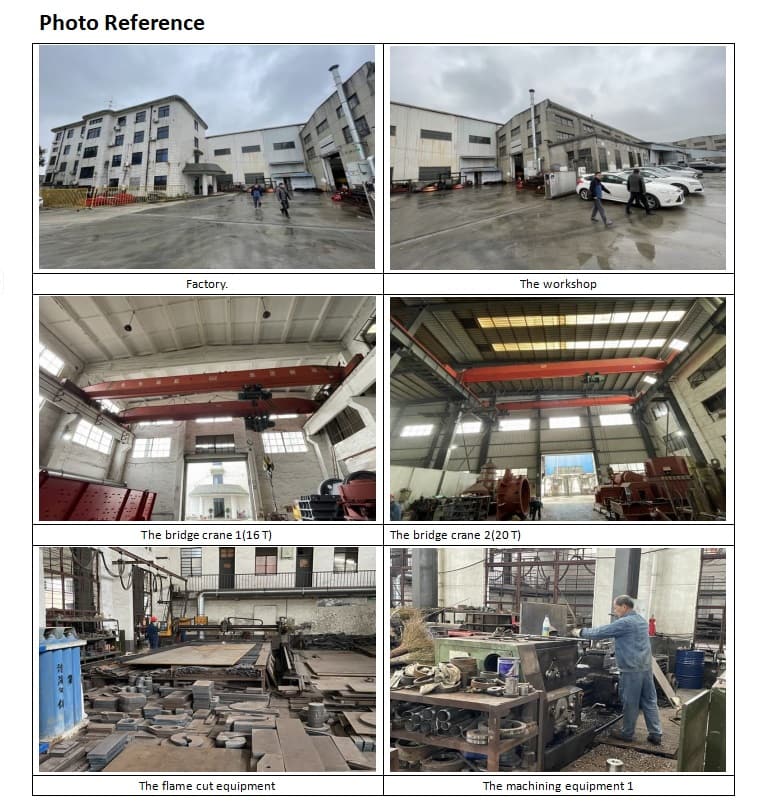

Facility and Infrastructure

-

China Factory Audit Checklist Premises and Layout: Examine the size, cleanliness, and organization of the factory premises. Check for proper zoning for different production areas.

- Building Condition: Inspect the condition of the building, including walls, floors, and ceilings, for any signs of damage or deterioration.

- Utilities and Services: Verify the availability and functionality of essential utilities such as water, electricity, and gas.

Production Processes – China Factory Audit Checklist

- Process Flow: Understand the production process flow and ensure its efficiency and logical sequencing.

- Equipment and Machinery: Inspect the condition, maintenance, and calibration of production equipment. Check for any outdated or malfunctioning machinery.

- Work Instructions: Review the availability and clarity of work instructions for each production stage.

Quality Management – China Factory Audit Checklist

- Quality Control Systems: Evaluate the existence and effectiveness of quality control measures throughout the production process.

- Inspection Procedures: Assess the inspection protocols for incoming materials, in-process products, and finished goods.

- Testing Facilities: Verify the availability and functionality of testing equipment and laboratories.

Materials and Supplies

- Material Handling: Observe the handling and storage practices of raw materials and components. Ensure proper labeling and traceability.

- Supplier Management: Review the management of suppliers, including their selection, evaluation, and performance monitoring.

- Inventory Management: Check the inventory control systems and stock levels to ensure optimal utilization of materials.

Labor and Workforce

- Workforce Skills and Training: Assess the skills and training levels of the workforce. Verify if they are adequately trained for their respective roles.

- Labor Conditions: Inspect working conditions, including safety measures, working hours, and employee welfare.

- Labor Relations: Evaluate the relationship between management and the workforce, including communication channels and grievance procedures.

Environmental and Safety

- Environmental Compliance: Ensure the factory complies with relevant environmental regulations, such as waste disposal and emissions.

- Safety Measures: Inspect safety protocols, including personal protective equipment, fire safety, and emergency response plans.

- Hazard Identification and Control: Identify potential hazards and assess the measures taken to control and mitigate them.

Documentation and Records

- Production Records: Review production records, including batch records, production logs, and quality reports.

- Quality Documentation: Examine quality management documentation, such as quality plans, inspection reports, and non-conformance reports.

- Legal and Regulatory Records: Verify compliance with legal and regulatory requirements by reviewing relevant documents.

Management Systems and Policies – China Factory Audit Checklist

- Quality Management System: Assess the implementation and effectiveness of a quality management system, such as ISO 9001.

- Business Policies: Review the company’s policies on issues such as quality, safety, and environmental protection.

- Continuous Improvement Initiatives: Inquire about ongoing improvement efforts and initiatives within the factory.

Supply Chain Integration – China Factory Audit Checklist

- Supplier Collaboration: Evaluate the level of collaboration and integration with suppliers in the supply chain.

- Customer Relationships: Assess the factory’s relationship with its customers and their feedback mechanisms.

Conclusion

Conducting a comprehensive factory audit in China is essential to ensure the quality, compliance, and reliability of the manufacturing operations. By following this detailed checklist, auditors can gain a thorough understanding of the factory’s performance and identify areas for improvement. Regular factory audits help maintain high standards, build trust with partners, and contribute to the success of the business in the global marketplace. It is crucial to adapt the checklist to the specific requirements and industry of the factory being audited to ensure a relevant and effective evaluation. With proper attention and diligence in conducting factory audits, companies can safeguard their interests and ensure the delivery of high-quality products from Chinese factories.

Learn more Successful Arctic module fabrication, steel structure, modular and skid, steelwork, supplier audit, DNV Class, Oil & Gas, welding supervisor, welding quality inspection, CWI CSWIP welding inspector, pump and pipe, stainless steel fabrication and CNAS ISO 17025 9712 NDT NDE practice via below-