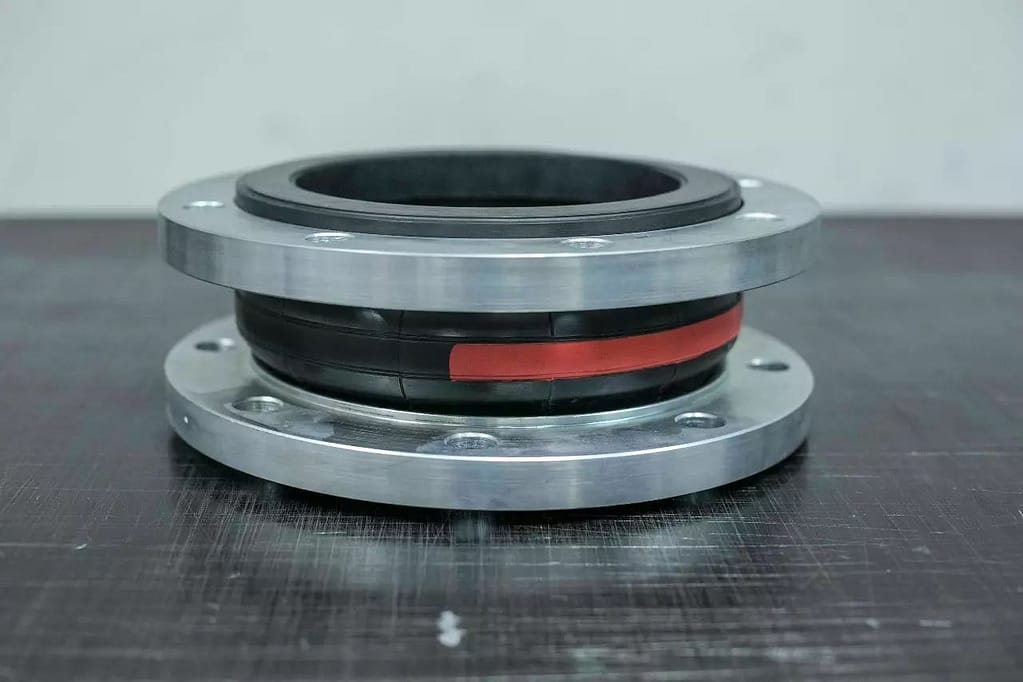

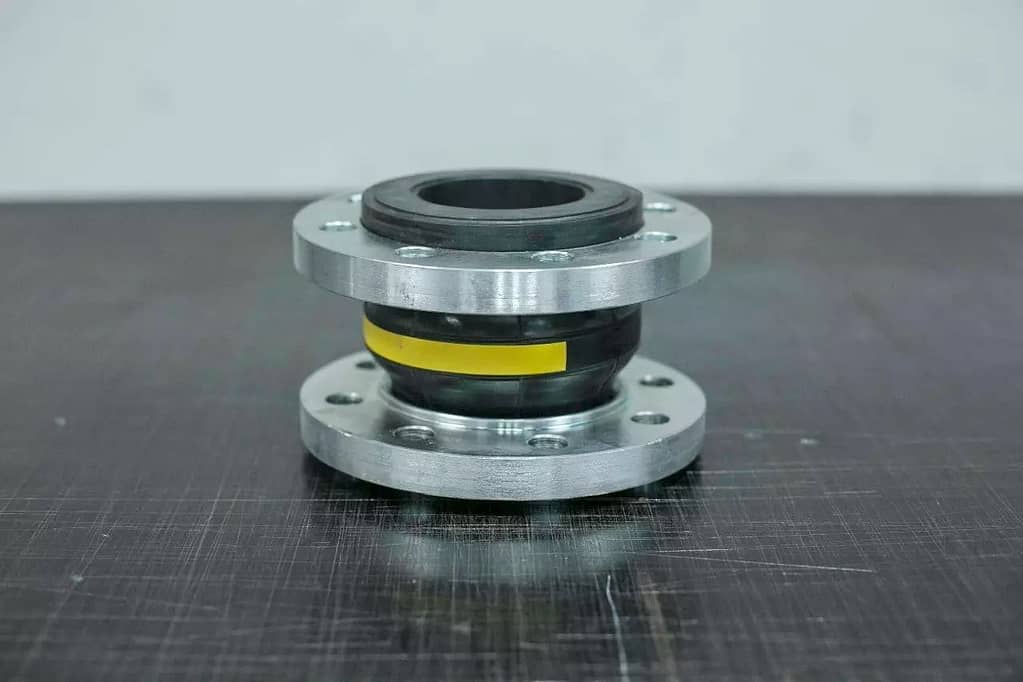

Expansion Joint

As a kind of elastic compensation element, expansion joint has the advantages of reliable operation, good performance and compact structure. Expansion joint widely used in chemical industry, construction, water supply, drainage, petroleum, light and heavy industry. Refrigeration, health, water heating, fire protection, electric power and other basic engineering fields, playing an important role in people’s life.

What is an expansion joint

The expansion joint have another name: the compensator. It is a flexible structure set on the container shell or pipe to compensate for the additional stress. As the temperature difference and mechanical vibration. Expansion joints There are two kinds of expansion joints: metal expansion joints and non-metal expansion joints.

Below, please compare the performance difference between metal expansion joints and non-metal expansion joints with Xiaobian, so as to have a more in-depth understanding of expansion joints.

-

Compensation function

Under the same dimensions, the compensation function of non-metal expansion joint is much larger than that of metal expansion joint. Especially for the compensation function of transverse displacement, the compensation function of non-metallic expansion joints is almost an order of magnitude larger than that of metal expansion joints. -

Compensate for force majeure

The expansion joint is like an elastic body, which will produce resistance after being shrunk or stretched, and the resistance of the metal expansion joint is much greater than that of the non-metal. This resistance is too large, it is unfavorable to the system, and it will break the surrounding equipment. -

High temperature and corrosion resistance

The material of non-metallic expansion joint not only has good high temperature resistance, but also has acid and alkali resistance. The yield limit of ordinary carbon structural steel is equal to zero at 600℃, and the temperature will be oxidized and peeled. Carbon steel expansion joints are easy to crack in the working process, stainless steel expansion joints in low temperature environment, low leakage point corrosion will occur, and its cost is also considerable. -

Heat preservation and energy saving performance

The structure of the non-metallic expansion joint itself has thermal insulation performance. The metal expansion joint does not have this condition, in order to keep heat, the outer layer of the metal expansion joint is also covered with a layer of insulation. -

Maintain the replacement performance

Non-metal expansion joint in the normal service life cycle, no maintenance; Non-metal expansion joints are much more convenient to replace than metal expansion joints. -

Service life

The service life of the expansion joint is closely related to the environmental conditions. Non-metal expansion joints have better wear resistance and corrosion resistance. Relatively speaking, the life of non-metal expansion joints will be longer than that of metal expansion joints under the same conditions. -

Use pressure

Thanks to the flexible design and the special materials used, the non-metallic expansion joint can withstand greater working pressure.

Thanks to the flexible design and the special materials used, the non-metallic expansion joint can withstand greater working pressure. -

Use media

Metal expansion joint suitable for liquid, gas, powder. Non-metallic expansion joints can be either gas or liquid.

As an important category of non-metallic expansion joints, rubber expansion joints have a large displacement compensation ability, which can be compensated for axial, transverse and angular displacement, reduce noise, reduce vibration and a certain anti-corrosion ability.

Learn more our project quality managemet, QAQC and third party inspection (TPI), NDT practices thru below link.

Thanks to the flexible design and the special materials used, the non-metallic expansion joint can withstand greater working pressure.

Thanks to the flexible design and the special materials used, the non-metallic expansion joint can withstand greater working pressure.