GB/T 41655-2022 “Non destructive Testing – Ultrasonic Testing – Welding, Rolling, and Explosive Composite Coating Testing Techniques” Process Method Interpretation

The use of welding, rolling, and explosion processes can achieve metallurgical bonding of one or more metals with different chemical and mechanical properties at the interface to form composite materials. It can greatly improve the thermal expansion, strength, fracture toughness, impact toughness, wear resistance, electrical properties, magnetic properties, and many other properties of a single metal material. It can also be made into composite plates, composite strips, composite foils, composite pipes, composite rods, composite wires, composite profiles, etc. Therefore, such processes are widely used in petroleum, chemical industry, shipbuilding, metallurgy, mining, machinery manufacturing, power, water conservancy, transportation, environmental protection, pressure vessel manufacturing, food, brewing, pharmaceutical and other fields.

The interface bonding state of metal composite materials has a significant impact on composite materials, and many composite material product standards classify them based on interface bonding rate (bonding degree). Due to the fact that ultrasonic testing technology is aimed at detecting internal discontinuities in materials, it is an important non-destructive testing method and also the most mature and widely used method for testing the interface bonding quality of composite materials both domestically and internationally.

GB/T 41655-2022 “Non destructive Testing – Ultrasonic Testing – Welding, Rolling, and Explosive Composite Coating Testing Technology” is a specialized ultrasonic testing method standard for the formation of coatings by welding, rolling, and explosion. This standard was developed for the first time in China and has become an important part of the series of standards for non-destructive testing of welds in China. It provides a unified and rigorous ultrasonic testing specification for parts produced by welding, rolling, and explosive welding technologies for mechanical equipment, pipelines, ships, bridges, steel structures, and other products. It is playing an increasingly important role in ensuring the quality and safety of major equipment manufacturing and engineering construction in the country.

This article introduces the method of manual ultrasonic testing using single crystal or twin crystal probes based on GB/T 41655-2022, which includes planar or volumetric discontinuities in the cladding and interface formed by welding, rolling, and explosive welding using steel as the substrate in the standard.

- Ultrasonic testing system

The detection adopts ultrasonic pulse reflection technology. For two-dimensional and three-dimensional discontinuities parallel to the detection surface, a straight probe (twin or single crystal probe) should be used for detection using longitudinal waves. For discontinuities in other directions, longitudinal wave twin crystal oblique probes can be used for detection. The nominal frequency of the probe should be selected based on the testing purpose and material characteristics, and the recommended probe frequency is 2-6 MHz.

The longitudinal wave refraction angle should be between 65 ° and 80 ° when using a longitudinal wave twin crystal oblique probe for detection. The tilt angle, shape, and size of the chip should be selected to ensure that the depth range of optimal sensitivity can cover areas where discontinuities are detected. When the detection of the coating cannot be carried out, it is recommended to use a longitudinal wave single crystal oblique probe from the side of the substrate to detect the coating at a 45 ° refractive angle.

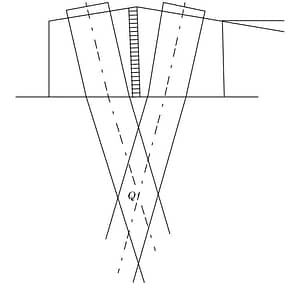

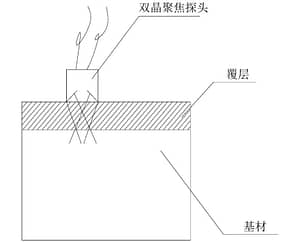

The manufacturer of twin crystal focused straight (oblique) probes should provide the depth range of the probe’s optimal detection sensitivity, which is the focal zone. The Q-point in the diamond shaped area of beam focusing is the most sensitive point, and the depth of the Q-point is the optimal detection depth. When detecting the covering layer, the corresponding focusing probe should be selected based on the thickness of the covering layer. The morphology of the dual crystal focusing probe is shown in Figure 1; Control the focal point of the probe’s receiving and sending at the interface between the coating and the substrate, and the coverage area of the focusing area is shown in Figure 2.

Figure 1 Morphology of Double Crystal Focusing Probe

Figure 2 Focus Area Coverage Area

Learn more our project quality managemet, QAQC and third party inspection (TPI), NDT practices thru below link.-

https://www.jsc-safe.com/mechanical-inspection-installation-commissioning/