How to Distinguish Forging Crack, Heat Treatment Crack and Raw Material Crack?

How to Distinguish Forging Crack, Heat Treatment Crack and Raw Material Crack? – Type of crack: Raw Material Crack, heat treatment crack, forging crack, etc..

Forging cracks can be subdivided into:

(1) Forging crack caused by raw material defect;

(2) Forging cracks caused by improper forging process.

Purpose of forging:

(1) Forming requirements;

(2) Improve the internal structure of the material, refine the grain, uniform element composition and structure;

(3) Make the material more compact, streamline distribution is more reasonable;

(4) Through a reasonable post-forging heat treatment, for the next process services.

Therefore, forging forging raw material internal defects is the responsibility.

Large-scale castings and forgings often start from ingot forging directly. There must be a lot of casting defects in ingot, obviously, reasonable forging, can be one of the so-called”Defects” forging. Therefore, the rationality of forging process is the main reason to determine whether the forging will crack.

Of course, relative to a certain stable forging process, if prior to the forging of raw materials to put forward a clear raw material defect level control requirements, when the quality of raw material exceeds the requirement and cracks appear in the original forging process, we can regard as”Forging cracks caused by raw material defects”.

1.Forging cracks

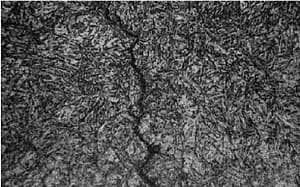

The forging crack is usually formed at high temperature. When the forging deformation occurs, the crack expands and touches air. Therefore, under the microscope of 100X or 500X, it can be seen that the crack is filled with oxide skin and the two sides are decarburized. The microstructure is ferrite, and its morphological characteristics are that the crack is relatively thick and exists in many forms, without fine tip, relatively round and pure, and without fine directivity, sometimes some of the forging cracks appear more fine. The crack is not fully decarburized but semi-decarburized.

2.Crack in heat treatment

There are obvious differences in properties and morphology between the cracks formed during quenching and forging. For structural steel, the heat treatment temperature is generally much lower than the forging temperature, even for high-speed steel, high-alloy steel, the heating time is much less than the forging temperature.

Because of high heating temperature, long holding time or fast heating, early cracking will occur in the heating process. The crack is distributed along the boundary of the larger grain, and there is a slight decarburization structure on both sides of the crack, however, there is oxide scale in the crack and its tail. Sometimes due to high temperature instrument failure, the temperature is very high, resulting in parts of extremely coarse structure, the crack along the coarse grain boundary distribution.

3.Causes of forging crack and heat treatment crack

(1) Forging crack cause:

In the forging process, steel has surface and internal defects, such as hairline, sand hole, crack, inclusion, subcutaneous bubble, shrinkage, white spot and interlayer, etc. , can be the cause of cracking in forging. In addition, due to forging process or improper operation, such as overheating, over-burning or final forging temperature is too low, after forging cooling speed is too fast, will also cause forging cracking.

(2) Causes of heat treatment cracks:

Quenching crack is a macroscopic crack, which is mainly caused by macroscopic stress. In the actual production process, the steel work piece often increases the quenching internal stress because of the unreasonable structure design, the improper steel material selection, the incorrect quenching temperature control, the unsuitable quenching cooling speed and so on, on the other hand, because of increasing the sensitivity of micro-cracks, increasing the number of micro-cracks and decreasing the brittle fracture resistance SK, therefore, the possibility of forming quenching crack is increased.

4.The factors affecting quenching crack

There are a lot of factors that affect quenching crack. Here we will only introduce some common situations in production.

(1) Quenching crack caused by existing defects in raw material: if there are cracks or inclusions on the surface and inside of raw material, which are not found before quenching, it is possible to form quenching crack;

(2) Crack caused by inclusion: if the internal inclusion of the part is serious, or because of the inclusion itself has a serious hidden crack, quenching will be likely to produce cracks;

(3) Quenching crack caused by poor original structure;

(4) Quenching crack caused by improper quenching temperature: quenching crack caused by improper quenching temperature, there are two general cases:

- The indicating temperature of the instrument is lower than the actual temperature of the furnace, so that the quenching temperature is on the high side, which causes the quenching to overheat and leads to the cracking of the workpiece. There are coarse grain and coarse martensite in the microstructure of superheat quenched cracking.

- If the actual carbon content of the steel is higher than that specified by the steel grade, the quenching temperature of the steel will be raised when it is quenched according to the normal quenching process of the original grade, the quenching crack is caused by the increase of stress during quenching.

(5) Quench crack caused by improper quenching.

(6) Quench crack caused by machining defects.

(7) The influence of the part shape on the quenching crack.

(8) Failure to temper in time.

5.The method of crack resolution

Firstly, pay attention to the difference between quenching crack and grinding crack.

Secondly, pay attention to where the crack occurs.

Thirdly, by observing the fracture surface of parts to distinguish between quenching cracks or forging cracks before quenching or other conditions caused by the cracks.

Fourthly, in microstructure, quenching crack is intergranular fracture, if it is not intergranular fracture, but intergranular fracture, then it is fatigue crack.

Fifth, if there is a decarburization layer around the crack, it is not a quenching crack, but a pre-quenching crack, because the quenching crack is produced during quenching cooling, decarburization will never occur.

Learn more our project quality managemet, QAQC and third party inspection (TPI), NDT practices thru below link.-