Method for Determination of Defect Length in Ultrasonic Testing

Method for Determination of Defect Length in Ultrasonic Testing – When the defect size in the workpiece is larger than the beam section, the length measurement method is usually used to determine the defect length.

The length measurement method is based on the defect wave height and the probe moving distance to determine the size of the defect.

The defect length determined by the prescribed method is called the indicated defect length.

Because the orientation, property and surface state of defects in the actual workpiece can affect the echo height of defects, the indicating length of defects is always less than or equal to the actual length of defects.

The length measurement method can be divided into relative sensitivity method, absolute sensitivity method and end-point peak value method.

1. Relative sensitivity length measurement

The relative sensitivity length measurement is based on the maximum echo of the defect, moving the probe along the length of the defect and reducing the DB value.

The DB values are reduced by 3DB, 6dB, 12dB, 20dB and so on. The common methods are 6DB method and endpoint 6DB method.

(1) 6DB method (half wave height method)

The 6DB method is also called the half-wave height method because the wave height is exactly half of the original after being reduced by 6DB. The practice of the half-wave height method is to move the probe to find the maximum reflected wave of the defect (which can not reach saturation) and then move the probe left and right along the defect direction. When the defect wave height is reduced by half, the distance between the center lines of the probe is the indicated length of the defect.

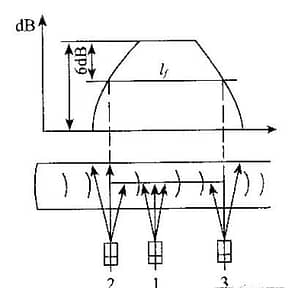

The concrete method of 6DB is to adjust the attenuator to reduce the defect wave height to the reference wave height after moving the probe to find the maximum reflection wave of the defect. The attenuator is then used to increase the sensitivity of the instrument by 6DB, and the probe is moved along the defect direction. When the defect wave height falls to the reference wave height, the distance between the center lines of the probe is the indicated length of the defect, as shown in Figure 1.

Half-wave height method (6DB method) is a commonly used method for defect length measurement. It is suitable for the case that the defect wave has only one high point during the scanning of length measurement.

(2) Endpoint 6DB method (endpoint half-wave height method)

When the reflected wave height of each part of the defect changes greatly, the endpoint 6DB method is used to measure the length.

When the defect is found, the probe moves left and right along the defect direction to find the maximum reflected wave at both ends of the defect, moving the probe left and right, the distance between the center lines of the probe is the indicated length of the defect when the reflected wave height at the endpoint is reduced by half (or 6 db) , as shown in Figure 2.

This method is suitable for the case that the reflected wave of defects has many high points in the scanning process of length measurement.

The half-wave height method and the end-point 6DB method both belong to the relative sensitivity method, because they measure the defect length by the maximum reflected wave of the defect itself or by the maximum reflected wave of both ends of the defect itself.

2. Absolute sensitivity length measurement

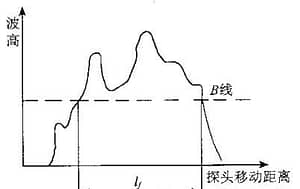

The absolute sensitivity length method is a method in which the probe moves in parallel with the length of the defect under certain conditions of the sensitivity of the instrument, is the indicated length of the defect.

The defect indication length measured by absolute sensitivity length measurement method is related to the length measurement sensitivity.

The length measurement has high sensitivity and large defect length, so the absolute sensitivity method is often used in automatic flaw detection.

3. Endpoint Peak method

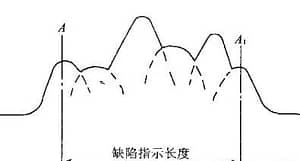

If the peak value of the reflection wave of the defect is fluctuating and there are many high points, the moving length of the probe between the maximum value of the reflection wave at both ends of the defect can be determined as the defect indication length, as shown (figure: 4) .

This method is called the endpoint peak method. The defect length measured by endpoint peak method is smaller than that measured by endpoint 6DB method. The end-point peak method is only suitable for the case that the reflection wave of defects has several high points in the scanning process of length measurement.

Learn more our project quality managemet, QAQC and third party inspection (TPI), NDT practices thru below link.-