Mineral Processing, Mining Process

Mining engineers employed at an established mine may serve various roles, including operations enhancement, mineral prospecting, and optimizing mine capitalization, deciding where to allocate additional equipment and staff within the mine. These engineers might also oversee and manage operations or engage in equipment and mineral sales. Apart from their engineering and operational duties, they could function as managers of environmental, health, and safety aspects or as design engineers.

Mining practices depend on the mineralogy, geology, and location of the resources being extracted. Factors such as mineral hardness, stratification, and accessibility influence the chosen extraction method.

Mining is broadly categorized into surface and underground operations, and sometimes both methods are used simultaneously in the same mining site. The approach to mineral extraction varies based on the chosen mining method.

Surface Mining

Surface mining, mineral accounts for 90% of global mineral production by tonnage. Also known as open pit mining, it targets mineral formations close to the surface. Ore is extracted by removing overlying material, often altering the land’s natural features, shape, topography, and geological composition.

Surface mining techniques include quarrying and excavating minerals with cutting, cleaving, and breaking machines. Explosives are commonly used to aid in the breaking process. Hard rocks like limestone, sand, gravel, and slate are typically quarried in benches. Softer minerals like clay and phosphate are extracted through strip mining using mechanical shovels, track dozers, and front-end loaders. For smoother coal seams, this method is also effective.

Placer mining involves dredging minerals from the bottoms of lakes, rivers, streams, and even the ocean. Additionally, in-situ mining employs dissolving agents on the ore body from the surface, pumping out the ore for further processing. Hydraulic mining uses water jets to wash away either the overburden or the ore itself

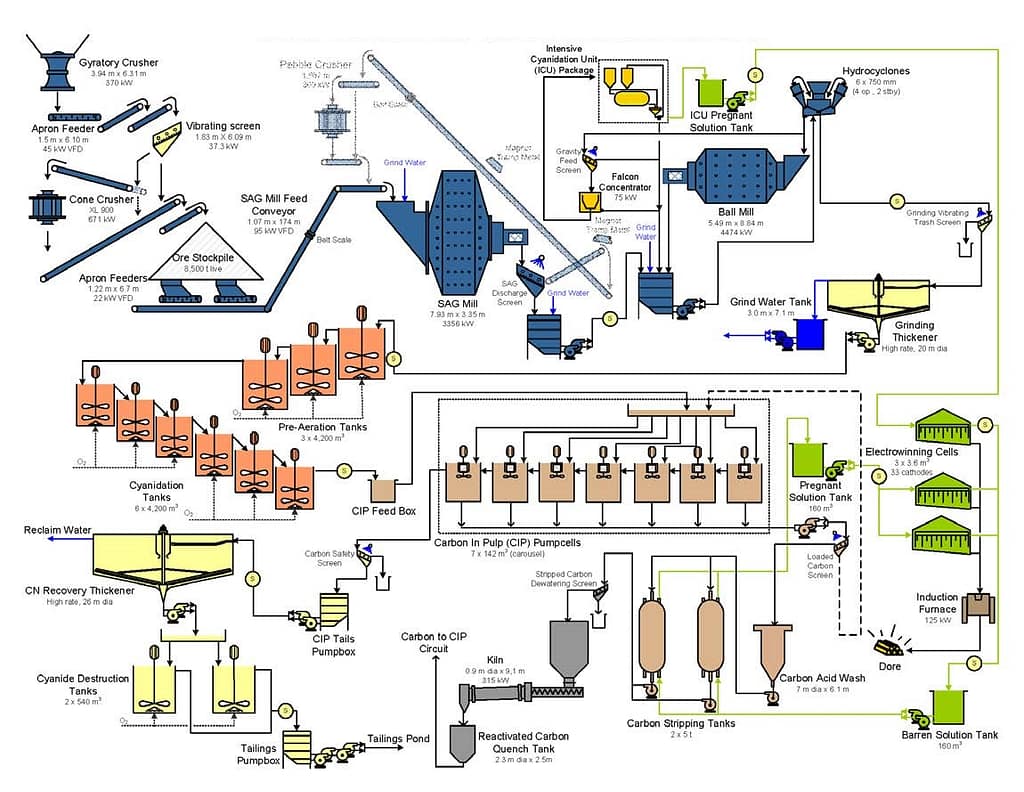

Mining Process, Mineral Process Mainly Involved:

Blasting

Blasting, a crucial step in mining, employs explosives to disintegrate rock formations and facilitate ore extraction. This process harnesses the heat and intense pressure generated by detonated explosives to shatter the rock mass. High explosives, varying in composition and performance, are commonly used. The mining engineer is tasked with selecting and strategically placing these explosives to ensure optimal efficiency and safety. Blasting occurs throughout various stages of mining, from infrastructure development to ore production. An alternative to high explosives are Cardox blasting cartridges, which utilize liquid carbon dioxide and were invented in 1931, becoming widespread in coal mines from 1932. These cartridges work by heating the liquid carbon dioxide until it bursts through a disk, creating a physical explosion of the supercritical fluid.

Leaching

Leaching refers to the extraction or loss of specific materials from a carrier into a liquid, often a solvent. This method finds frequent application in the extraction of rare-earth metals.

Flotation

Flotation, also known as floatation, pertains to the buoyancy-related phenomena of minerals. It stands as the most commonly used technique for metal separation.

Electrostatic Separation

This method separates minerals based on their distinct electro-characteristic differences.

Gravity Separation

Gravity separation is an industrial technique that separates two components of a mixture, either in suspension or as a dry granular blend, leveraging gravity when feasible.

Magnetic Separation

Magnetic separation involves extracting magnetically susceptible materials from a mixture by employing magnetic force.

Hydraulic Separation

Hydraulic separation utilizes density differences to segregate minerals. Prior to this process, minerals are crushed to uniform sizes. Minerals of uniform size and density exhibit varying settling speeds in water, enabling the separation of target minerals