NDT – Magnetic Testing (MT) / Magnetic Particle Inspection (MPI) for Pressure Vessel

NDT – Magnetic Testing (MT) / Magnetic Particle Inspection (MPI) is widely used in nondestructive testing of pressure vessels. The testing methods are as follows:

The principle is:

The magnetic field will be applied to the specimen, steel and other strong magnetic materials can be strongly magnetized by the magnetic field. If there is a crack on the specimen, and the direction of the crack and the direction of magnetization is right angle, then the magnetic pole appears at the crack, and magnetic leakage field is produced.

When fine particles of magnetic particles enter the leakage field, they are attracted and left behind. Because the leakage magnetic field is wider than the crack, the accumulated magnetic powder can be easily seen by the naked eye.

When the magnetization is high enough, even if the crack is very small, it can form a clearly visible magnetic leakage field. If the fluorescent magnetizing fluid is used, then the small cracks, folds, pores, slag and other surface defects on the specimen will show up as yellow-green lines or dotted lines under UV irradiation.

Magnetic testing operations

Magnetic testing operations include pre-treatment, magnetization, application of magnetic particles, observation records and post-treatment (including demagnetization). The direction of the detected crack should be considered when magnetizing the specimen, and the magnetic field should be applied in the direction perpendicular to the crack direction.

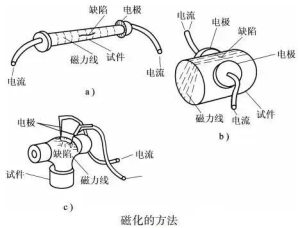

The actual applied magnetization method is shown in the diagram below, where the magnetic field direction is represented by a magnetic field line (dotted line) . Because the direction of the crack is often difficult to predict, it is often used in practice to obtain a magnetic field perpendicular to each other’s composite magnetization method.

The surface magnetic field strength

The surface magnetic field strength can be calculated from the size of the specimen and the current value.

Magnetic testing

Magnetic testing is highly accurate, it can identify surface crack and other shallow depth of the surface defects, but can not determine the depth of defects, can not be used to detect internal defects.

Magnetizing methods

There are many magnetizing methods, such as axial electrifying method, direct current electrifying method, electrode penetration method, coil method, inter-pole method, magnetic penetration method, etc. .

Learn more our project quality managemet, QAQC and third party inspection (TPI), NDT practices thru below link.-

https://www.jsc-safe.com/category/mining-metals/