NDT – UT of Common Types of Defects Echo and False Defects

Common Types of Defects Echo and False Defects:

Porosity:

The echo height of a single pore is low, the waveform is stable, and the reflected wave is approximately the same from all directions, and disappears with a slight movement of the probe. The dense pores are a group of reflected waves whose wave height varies with the size of the porosity.

Dot inclusion:

The echo signal of dot inclusion is similar to that of dot pore. The echo signal of slagging slag is zigzag, the reflectivity is low, the amplitude is not high, the waveform is often tree-like, there is a small peak on the side of the main peak, the amplitude changes when the probe moves, and it can be detected from all directions, the reflected waves vary in height.

Non-penetration:

In the thick double-sided weld, the non-penetration is in the middle of the weld, and the acoustic wave is similar to mirror reflection on the non-penetration surface. For one-sided root probe not, Weld head, similar to end angle reflection. Probe translation, no penetration waveform stability. The same human-induced reflected wave amplitude can be obtained for both sides of the weld.

Lack of fusion:

When the ultrasonic incident vertically on its surface, the echo height is large, when the probe translation, the waveform is more stable, both sides of the detection, the reflected wave amplitude is different, sometimes only from one side of the detection.

Crack echo:

Generally speaking, the crack echo is large, the amplitude is wide, and there will be multi-peak. When the probe moves, the reflected wave appears continuously, and the amplitude changes. When the probe rotates, the wave crest dislocates up and down.

Some common defects echo image:

(Not fused and unwelded)

(Crack)

(Porosity)

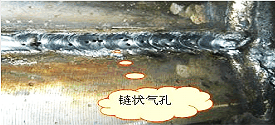

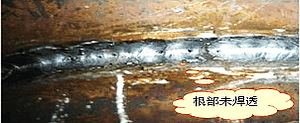

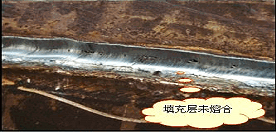

Common types of defects image:

(Chainlike stomata)

(The roots are not welded through)

(The filling layer is not fused)

(Crack in the bottom layer)

False defect echo is common in weld inspection

1 Instrument clutter

2 Probe clutter

3 Coupler Echo

4 Reflections from weld surfaces and grooves

5 Reflection wave caused by up and down dislocation of Weld

6 Fillet echo

Learn more our project quality managemet, QAQC and third party inspection (TPI), NDT practices thru below link.-