The Necessity of Ultrasonic Testing in Welding of Metallic Materials

The Necessity of Using Ultrasonic Testing in Welding of Metallic Materials – There are many problems in the welding process of metal materials, the most important of which are three aspects: internal defects, macro defects, micro defects. In order to better analyze the importance of using ultrasonic nondestructive testing, we first look at these three aspects of defects in detail.

Internal defects in welding of metallic materials

The internal defects of the welding structure of metal materials are: slag residue left in the weld during workpiece welding, and one is in the process of material welding. A hole formed by encasing a gas in molten metal. Another is in the workpiece welding process between the material and the formation of cracks.

Macroscopic defects in welding of metallic materials

The macroscopic defects of the welding structure of metallic materials are: the liquid metal flows from the weld to the non-uniform or non-fused base metal in the welding process, and forms the metal lump after cooling. During welding, the depth of melting exceeds the thickness of the workpiece, causing the molten metal to flow out of the back of the weld, forming a perforation.

Microdefects in welding of metallic materials

The micro-defects of metal welding structure mainly include: in the welding process, because of the non-standard welding technology, the local heating time is too long, which makes the welding grains become larger. The over-burning phenomenon in which the temperature is too high and stays at the welding place for a long time, causing the surface to oxidize or part of the surface to melt. In welding process, due to uneven heating cycle caused by internal components to one side of the accumulation of segregation phenomenon.

Application of ultrasonic testing in nondestructive testing of welding process:

Principle of ultrasonic testing technology

Ultrasonic detection technology is to detect the change of some physical properties of the object by using the influence of the echo characteristics of the object itself or its defects on the ultrasonic propagation. Ultrasonic testing takes advantage of the sound propagation properties of the medium, such as sound speed, attenuation coefficient, acoustic impedance, etc. , and the industrial abnormal acoustics of certain objects, for example, strength, elasticity, hardness, density, temperature, viscosity, concentration, flow rate, velocity, thickness, and so on, in order to take advantage of their relationship, the results are obtained by comparing these sounds. According to the received ultrasonic signal, the internal defect of the object is analyzed.

Characteristics of ultrasonic testing technology

The ultrasonic testing technology has the advantages of wide detection range, large detection depth and fast transmission speed, which is not only harmless to human body but also convenient for use in various places, the problems of product quality can be found in time to improve product safety. Using ultrasonic nondestructive testing technology in metal welding, we can judge the quality of weld according to the slight change of sound wave, and detect whether there is any problem or hidden trouble in welding. Therefore, ultrasonic nondestructive testing is an important innovation in metal welding industry.

Points for attention in the selection of ultrasonic nondestructive testing for metal welding

How to prepare for ultrasonic nondestructive testing of welding:

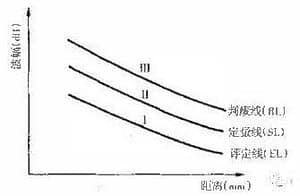

First of all, we should know the technical requirements of welding in drawing design, and select appropriate standards for ultrasonic nondestructive testing. For example, GB50205-95, which is divided into three levels, each level has its specific requirements.

Secondly, we should know the time of inspection, then we can carry out weld inspection. We should also know the thickness of the workpiece. Only when we know the specific requirements of the workpiece, then we can carry out ultrasonic nondestructive testing.

The ultrasonic nondestructive testing technology has played a revolutionary role in the metal material welding industry, and has been paid more and more attention in the mechanical industry and manufacturing industry, ultrasonic non-destructive testing (NDT) technology has become one of the important standards to measure the development level of a country’s industrial welding field, in line with the development trend of resource-saving society.

Learn more our project quality managemet, QAQC and third party inspection (TPI), NDT practices thru below link.-

https://www.jsc-safe.com/17025-cnas-non-destructive-testing-ndt/