Trenchless Construction: Revolutionizing Infrastructure Development

In the realm of modern construction and engineering, one of the most remarkable advancements is trenchless construction. This innovative approach has transformed the way we build and maintain infrastructure, offering a myriad of benefits that are changing the landscape of various industries. Trenchless construction refers to a set of techniques and methods that enable the installation, repair, and replacement of underground utilities and structures without the need for extensive excavation.

The history can be traced back to ancient times when rudimentary methods were used to lay pipes and conduits. However, it is in recent decades that this field has experienced significant technological advancements and widespread adoption. Today, trenchless construction techniques are used in a wide range of applications, from laying water and sewer pipes to installing telecommunications cables and gas pipelines.

One of the key advantages of trenchless construction is its minimal impact on the surrounding environment. Traditional excavation methods often result in large-scale disruption to the landscape, causing damage to roads, sidewalks, and other infrastructure. In contrast, trenchless techniques minimize the need for open excavation, reducing the amount of soil disturbance and the associated environmental impact. This not only helps to preserve the natural beauty of the area but also reduces the potential for soil erosion and sedimentation.

Furthermore, trenchless construction offers significant time and cost savings compared to traditional methods. By avoiding the extensive excavation and restoration work required with traditional construction, projects can be completed more quickly and efficiently. This reduces labor costs, minimizes traffic disruptions, and allows for faster project completion, which is particularly beneficial in urban areas where time is of the essence. The reduced need for heavy machinery and equipment also contributes to cost savings, as does the decreased risk of encountering unexpected underground obstacles or complications.

Another advantage of trenchless construction is the ability to access difficult-to-reach areas. Traditional excavation methods may be impractical or impossible in some locations, such as under busy roads or in areas with limited access. Trenchless techniques, such as horizontal directional drilling (HDD), allow for the installation of pipes and conduits through long distances and under challenging terrain, providing greater flexibility and expanding the possibilities for infrastructure development.

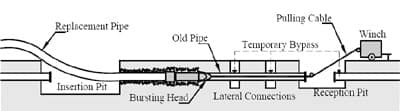

The various trenchless construction techniques available today include pipe bursting, sliplining, microtunneling, and auger boring, among others. Each technique has its own unique characteristics and applications, and engineers and contractors carefully select the most appropriate method based on the specific requirements of the project. For example, pipe bursting is often used for replacing existing pipes, while sliplining is commonly used for installing new pipes in existing conduits. Microtunneling is suitable for longer and more complex projects, while auger boring is typically used for shorter distances and smaller diameter pipes.

Despite the many advantages of trenchless construction, there are also some challenges and limitations that need to be addressed. One of the main challenges is ensuring the quality and integrity of the installed infrastructure. Trenchless techniques rely on specialized equipment and skilled operators, and any errors or defects can have significant consequences for the performance and longevity of the infrastructure. Additionally, the initial investment in trenchless equipment and technology can be relatively high, which may limit its adoption in some regions or projects with limited budgets.

In the field of trenchless construction, ongoing research and development are crucial for improving the existing techniques and developing new ones. Advancements in materials science, robotics, and sensing technologies are opening up new possibilities for more efficient and reliable trenchless construction. For example, the development of smart sensors and monitoring systems can provide real-time data on the condition of the installed infrastructure, enabling proactive maintenance and reducing the risk of failures.

The adoption of trenchless construction is not only limited to developed countries but is also gaining traction in developing regions around the world. As infrastructure needs continue to grow, and the importance of sustainable development becomes increasingly recognized, trenchless construction offers a viable solution for meeting these demands. By minimizing the environmental impact, reducing costs and time, and providing greater flexibility, trenchless construction is playing a crucial role in shaping the future of infrastructure development.

In conclusion, trenchless construction is a revolutionary approach that is transforming the way we build and maintain infrastructure. Its numerous benefits, including minimal environmental impact, time and cost savings, and access to difficult-to-reach areas, make it an attractive option for a wide range of projects. While there are some challenges and limitations, ongoing research and development are driving the advancement of this field, ensuring that trenchless construction continues to evolve and play a vital role in the development of our modern society. As we look to the future, it is clear that trenchless construction will remain an important tool in the hands of engineers and contractors, helping to build a more sustainable and efficient infrastructure for generations to come.

Learn more Successful Arctic module fabrication, steel structure, modular and skid, steelwork, supplier audit, DNV Class, Oil & Gas, welding supervisor, welding quality inspection, CWI CSWIP welding inspector, pump and pipe, stainless steel fabrication and CNAS ISO 17025 9712 NDT NDE practice via below-

https://www.jsc-safe.com/steel-structures-modules-machining/