Trenchless Technology Trenchless Construction Drilling Pipe

Trenchless Technology Trenchless Construction Drilling Pipe

Trenchless technology represents a kind of subsurface construction methodology that necessitates minimal or no continuous trenching. Constituting a swiftly expanding segment of the construction and civil engineering domain, it can be delineated as “a set of techniques, materials, and machinery that can be employed for installing fresh or substitute underground infrastructure, or for revamping the prevailing ones, with negligible interruption to surface traffic, commerce, and other pursuits.”

Trenchless Technology Trenchless Construction Drilling Pipe

Trenchless construction encompasses various methods such as tunneling, microtunneling (MTM), horizontal directional drilling (HDD), also referred to as directional boring, pipe ramming (PR), pipe jacking (PJ), moling, horizontal auger boring (HAB), and other underground pipeline and cable installation techniques that minimize excavation. Large-scale subsurface projects like those employing a tunnel boring machine (TBM) or drilling and blasting methods are extensions of this concept on a grander scale. The distinction between trenchless methods and other underground construction lies primarily in the size of the tunnel being constructed.

This approach necessitates careful consideration of soil properties and surface loads. In sandy soils, shallow water tables, or areas anticipating significant loads like urban traffic, the excavation depth must be sufficient to prevent surface pressure from compromising the bore, thereby avoiding the risk of surface collapse.

Trenchless rehabilitation

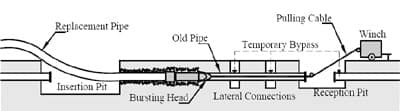

Trenchless rehabilitation encompasses various methods like spiral wound lining, sliplining, thermoformed pipe, pipe bursting, shotcrete, gunite, cured-in-place pipe (CIPP), grout-in-place pipe, mechanical spot repair, and other non-excavation or minimal excavation techniques for repairing, rehabilitating, or replacing existing underground pipes and structures. Mechanical spot repairs are employed where structural integrity needs to be restored in damaged pipelines. Methods like sliplining, CIPP, and thermoformed pipe lining involve inserting a new liner into an old pipe, followed by the application of heat and/or pressure to expand the liner and fill the pipe. CIPP methods use a carrier (felt or fiberglass) impregnated with curable resin, activated by heat, UV light, or ambient conditions, to create a “pipe within a pipe” structure. Pipe bursting breaks the existing pipe from the inside, pushing the fragments outward while simultaneously drawing in a new pipe to replace the old one. Other techniques primarily address localized leaks. Generally, trenchless rehabilitation methods prove more cost-effective than traditional excavation and replacement methods.

Trade associations

Various industry associations represent the trenchless technology sector, besides standing committees within numerous water and sewer-related associations. The International Society for Trenchless Technology, founded in 1986, has 25 active national trenchless technology societies as its affiliates.

In the United Kingdom, the United Kingdom Society for Trenchless Technology (UKSTT), established in 1993, provides a Trenchless Enquiry Service to assist in all aspects of trenchless technology.

In the United States, The National Association of Sewer Service Companies (NASSCO), founded in 1976, is the oldest association with a focus on trenchless methods. The North American Society for Trenchless Technology (NASTT) was created in 1990.

Multiple organizations publish technical journals to educate readers about these advanced techniques.