What are the Ultrasonic Testing (UT) Methods?

Ultrasonic Testing (UT) Methods – Sound is a physical phenomenon, although its instantaneous existence is very obvious, but it does not cause any permanent changes. This is why sound (low energy) is ideal for nondestructive testing, where the state of the object under test is determined by obtaining accurate information. For this purpose, a method is needed that produces a definite reaction within the subject without changing its state.

“Passivity” is the most important feature that sound is required for material testing.

1. Passive acoustics is also used in the special field of acoustic emission, in which sound waves are generated internally by spontaneous changes in material conditions. Sound waves are mechanical waves and therefore need to act as a medium for conducting them. Whether it is a solid, a liquid, or a gas, each material can be evaluated for its particular effects on sound waves.

2. The whole basis of ultrasonic testing is the effect of sound wave propagation in the medium under test. Changes experienced by sound waves can be measured and used to assess the state of the material.

3. The evaluation of material properties can only be done indirectly. By means of model and empirical correlation, some changes in acoustic signals can be interpreted as changes in material structure or the presence of inclusions. The assessment of material quality always depends on the reliability of the concept of signal interpretation.

Interference in the propagation of sound used to evaluate materials is always based on the same principle: interference caused by interfaces. For example, interference caused by a limiting or macroscopic interface (such as a crack) and a microscopic interface (such as a grain boundary) of the test sample. Interference caused by absorption. This is mainly due to internal friction generated by the energy conversion. In this case, the assessment is made by the signal transmitted through the medium or reflected at the interface.

The basic effects of these interventions lead to different ultrasonic detection methods:

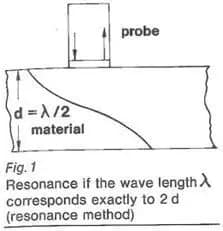

Resonance:

The reflection between two parallel limiting surfaces of the test sample is used (Fig. 1) to detect the specific acoustic properties of the material by the resonance phenomenon. The properties and structure of a material can be inferred by generating resonant frequencies of sound waves in the material and observing the reflected or transmitted signals.

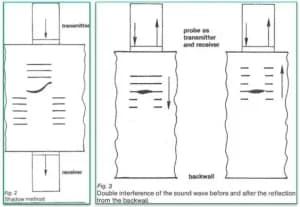

Transmission:

The method of transmission is also called penetration or shading. The method utilizes the masking effect of the material interface (material discontinuity) . The method uses two opposite ultrasonic probes, one as transmitter and one as receiver. The homogeneity and defects of materials are evaluated by detecting the propagation of ultrasonic waves in materials, including transmission, absorption and scattering. The“Mirror-shadow method”, in which the probe is located on the side of the test sample, can also be used (Fig. 2).

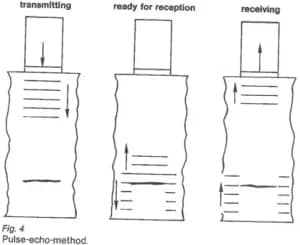

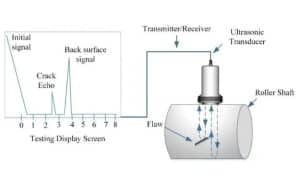

Echo:

The method utilizes a signal reflected by discontinuities in the material (fig. 4) . The transmitting probe may be identical to the receiving probe, or a separate transmitting and receiving probe may be used. The most important echo method, and the most commonly used of all ultrasonic detection methods, is the pulse echo method. By using ultrasonic pulses, it is possible to assess not only the size of the indication (echo amplitude) , but also the time of echo propagation. Therefore, data on the size and location of the reflector can be obtained. If you know the location of the reflector (from the bottom) , you can evaluate the material’s structure by propagation time. If you do not know the location of the reflector, but know the characteristics of the material (attenuation, sound speed) , you can carry out wall thickness measurement.

Learn more our project quality managemet, QAQC and third party inspection (TPI), NDT practices thru below link.-

https://www.jsc-safe.com/17025-cnas-non-destructive-testing-ndt/