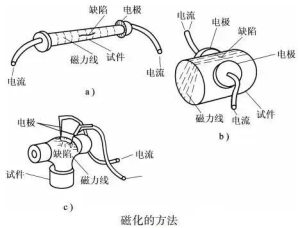

NDT – Magnetic Testing (MT) / Magnetic Particle Inspection (MPI) for Pressure Vessel NDT – Magnetic Testing (MT) / Magnetic Particle Inspection (MPI) is widely used in nondestructive testing of pressure vessels. The testing methods are as follows: The principle is: The magnetic field will be applied to the specimen, steel and other strong magnetic materials can be strongly magnetized by the magnetic field. If there is a crack on the specimen, and the direction of the crack and the direction of magnetization is right angle, then the magnetic pole appears at the crack, and magnetic leakage field is produced. When fine particles of magnetic particles enter the leakage field, they are attracted and left behind. Because the leakage magnetic field is wider than the crack, the accumulated magnetic powder can be easily seen by the naked eye. When the magnetization is high enough, even if the crack is very […]

MT

Five Steps to Calibrate Magnetic Testing (MT) Equipment Five Steps to Calibrate Magnetic Testing (MT) Equipment – There are many kinds of magnetic particle testing equipment, from small portable magnetic detector to wet horizontal magnetic detector to high current fixed magnetized power supply for large structures. If you follow ASTM E1444, ASTM E3024, ISO 9934, or NADCAP AC7114/2, you must calibrate your equipment every six months. No matter what type of magnetic particle testing equipment is used, five-step method can be used for equipment calibration. Step 1: verify the standard instrument to be used 1.This work requires standard reference instruments: shunts, ammeters, and excitation timers. Different instruments have different control configurations. Refer to the specification of the standard reference instrument for detailed operating procedures. 2.Check the calibration dates of these standard reference instruments-have they been calibrated in the past 6 months? 3.How much data do you need to test and […]